Terms of Use | Privacy Notice | Data Privacy Framework | Cookie Notice | DMCA | Whistleblowing |

© Altair Engineering Inc. All Rights Reserved.

Terms of Use | Privacy Notice | Data Privacy Framework | Cookie Notice | DMCA | Whistleblowing |

© Altair Engineering Inc. All Rights Reserved.

The Electric Mobility Revolution is Ready to Go Mainstream

OEMs, suppliers, and emerging vehicle manufacturers are investing billions to develop innovative electric vehicles and optimize development and production processes to deliver e-mobility to the masses. In the presentations below, learn how Altair works with the world’s leading manufacturers and suppliers to accelerate product development, enhance energy efficiency, and optimize integrated system performance.

Electric Vehicle Development Webinar Series

System Level Optimization of Key Electric Vehicle Powertrain Attributes

Gonçalo Pereira, Principal Applications Engineer at Altair presents at the 2019 UK e-Mobility Seminar. Trade-off Studies between Battery Pack, e-Motor, Range etc. System Model Generation to Explore Sensitivities.

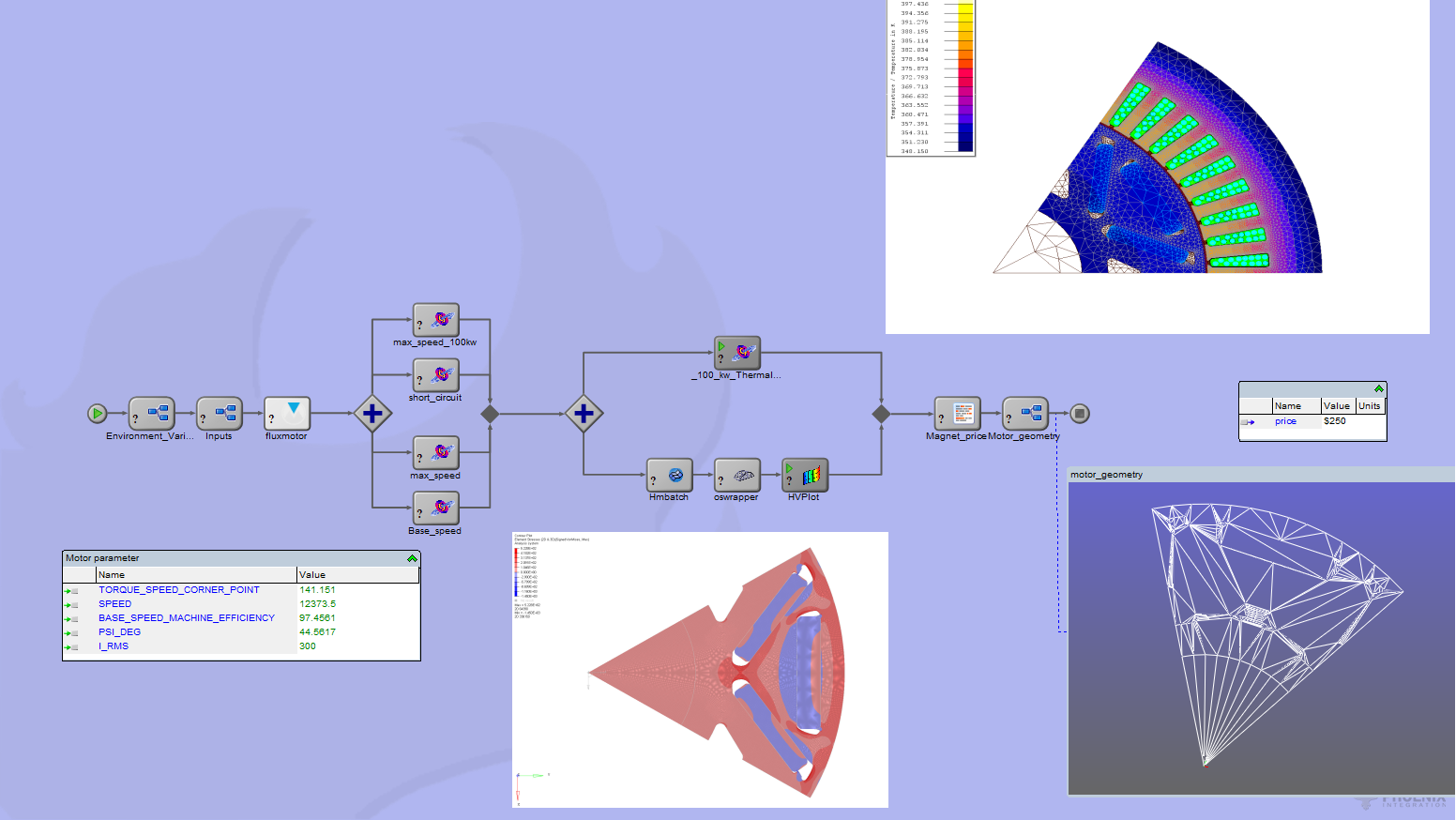

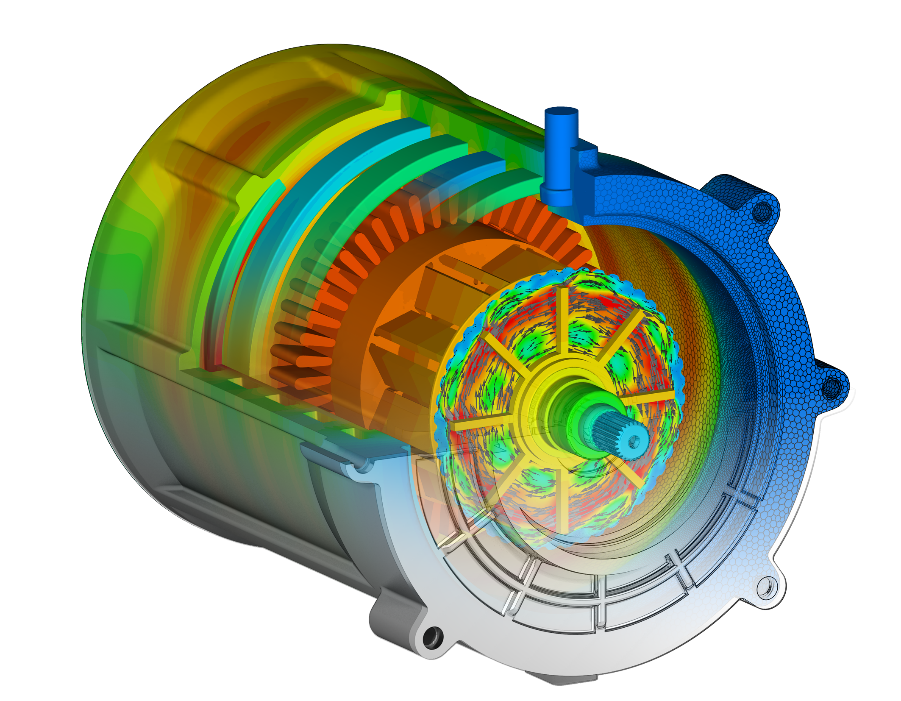

Simplifying Multidisciplinary Modeling of an Electric Motor

ModelCenter’s powerful integration capabilities simplify building automated multidisciplinary workflows. This enables the Altair Hyperworks software suite to be integrated in highly complex applications. In this example ModelCenter was used to solve an industrial multidisciplinary design problem, the design of an electric motor for an automobile.

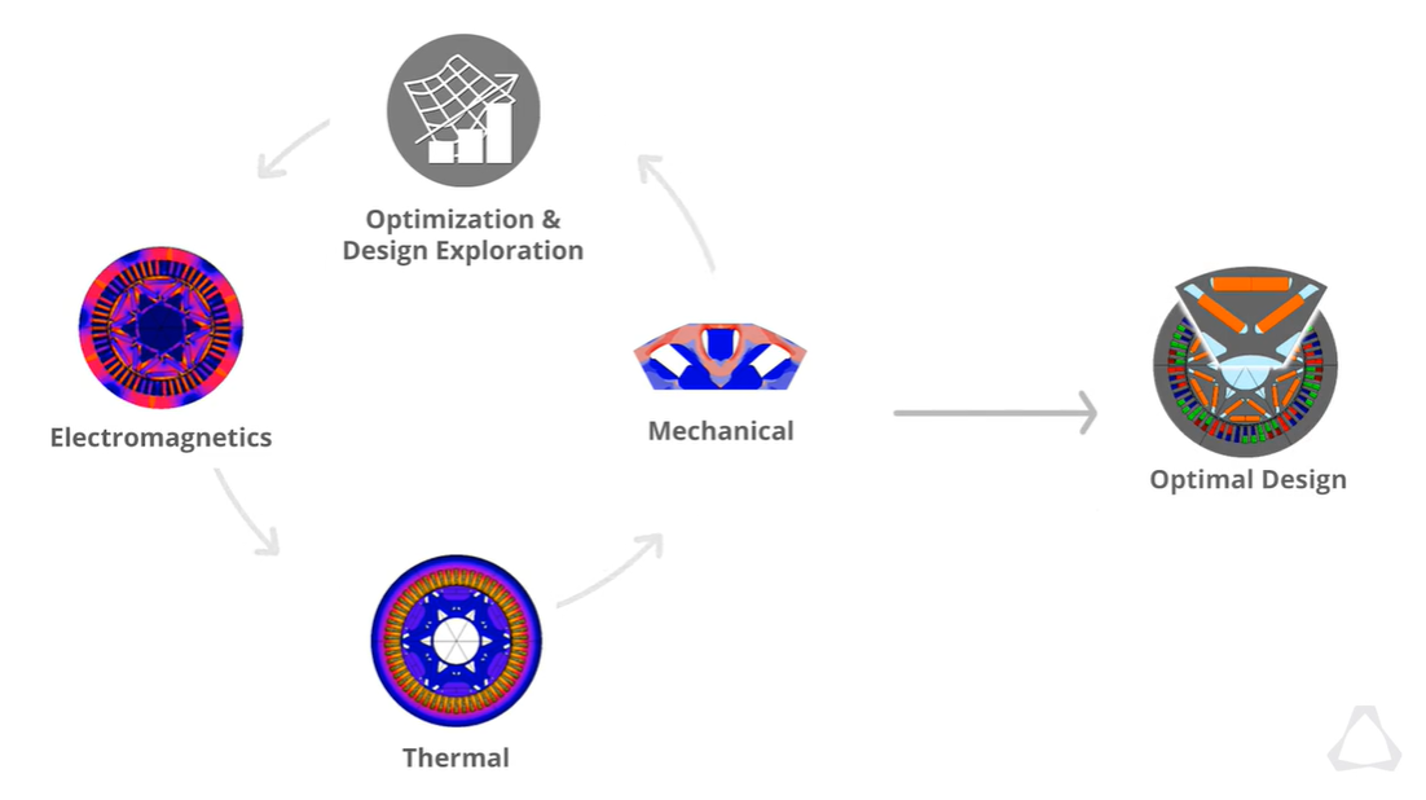

Mercedes AMG's Efficient and Automated Design Strategy for Multiphysics E-Motor Development

This presentation introduces an application of a unique, highly automatic, multi-physics design strategy for E-motors, based on a current program at Mercedes-AMG GmbH. The strategy considers essential development requirements including electromagnetics and thermal requirements, NVH, stress and durability. It accommodates for DOE, multi-objective optimization and design exploration methods to be used to explore and find feasible motor designs. The presentation will show how the strategy adds efficiency to the E-motor development process and how it impacts the total costs of development.

The Increased Importance of BIW & Powertrain Integration in Electric Vehicle Development

Jamie Buchanan, UK Technical Director at Altair presents at the 2019 UK e-Mobility Seminar. Global Review of the EV Architecture. Integration Opportunities (e.g. Battery System Packaging, BIW / Battery Tray Integration)

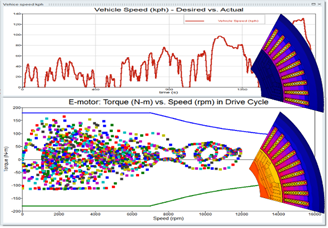

Improving Electric Vehicle Range with Advanced Losses Computation Considering PWM Across a Full Duty Cycle

Introducing electric traction in automotive brings new challenges for the design of electric machines. Designers must consider increasing constraints like efficiency, temperature, weight, compactness, cost but also stricter regulations, while reducing time to market. Fortunately, Altair proposes disruptive methodologies to make relevant choices in the early stage of the design, based on numerical simulation and optimization techniques.

e-Motor Weight and Cost Reduction

This webinar will introduce Altair's e-motor design and optimization solutions in a step by step process. We will discuss pre-design, magnetic computation and thermal analysis and show how optimization methods can help to optimize weight and cost at each step of the process (especially the weight of magnets) . We’ll demonstrate how Design of Experiments (DOEs) allows designers to run different types of optimization very quickly, which enables informed decisions at different stage of the design cycle.

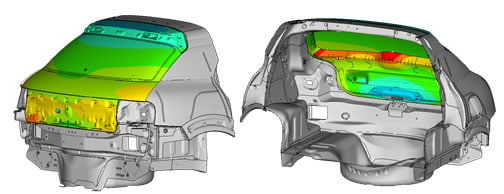

Predicting and Eliminating Squeak & Rattle Noise in Vehicle Interiors with PSA Peugeot Citroën

During the development of new vehicles, PSA Peugeot Citroën Group (PSA) wanted to take the lead in using simulation technology to detect squeak and rattle noise problems before physical testing was possible. The initiative led to a collaboration between PSA’s Method Development Engineering team and Altair to explore the use of simulation technologies and numerical optimization methods at an early stage of development.

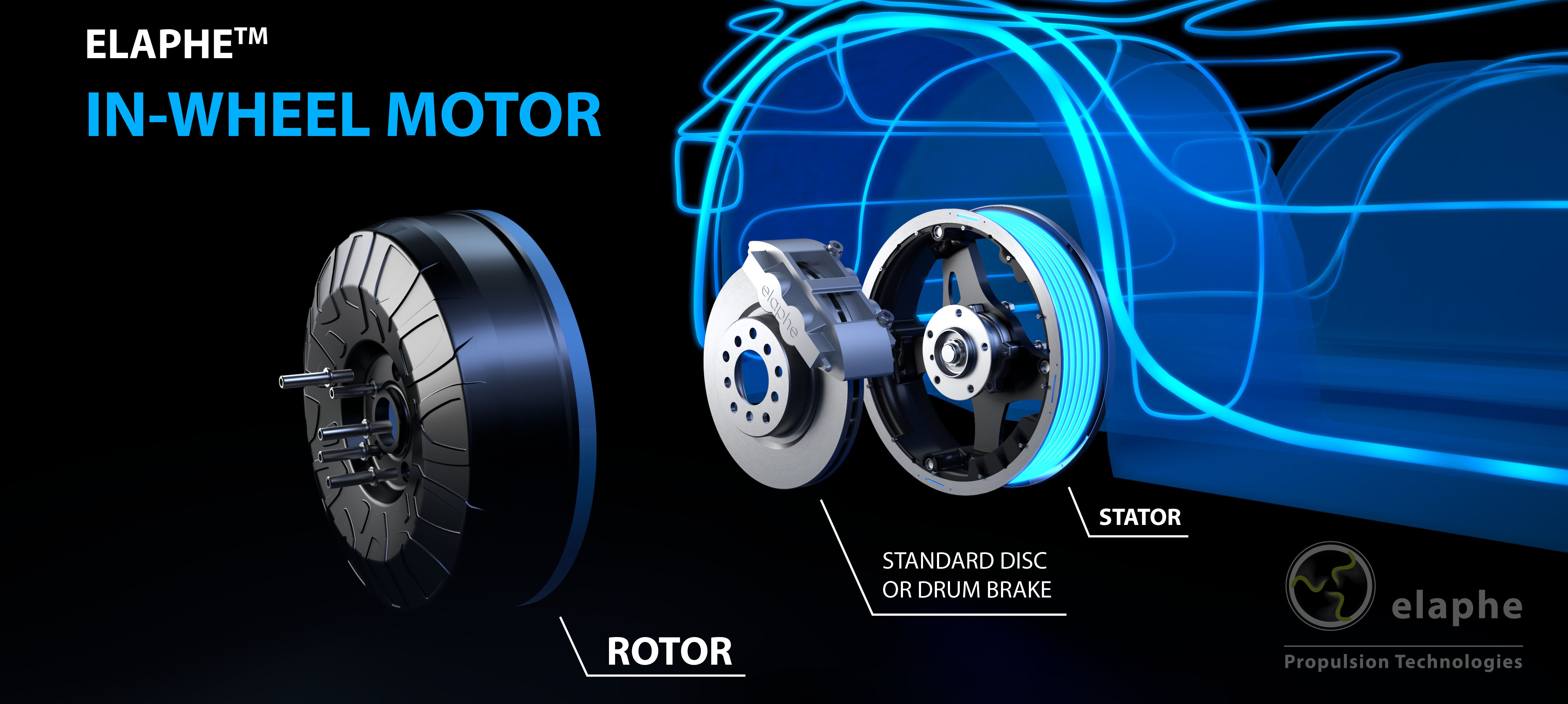

Coupled Electro-Magnetic and Acoustic Simulation of an In-Wheel Electric Motor

At Elaphe, the engineers have been facing the NVH challenges from the very beginning. The topology of this electric motor, which on the one hand enables the team to use the otherwise empty space inside the wheel, can on the other hand, result in some new and unexplored NVH challenges. The experience over the years has proven that NVH is a bottleneck in the design cycle of Elaphe's motors and this was the main motivation for a more automated and more user-friendly NVH simulation workflow. Within the NVH, noise radiation was the area Elaphe was most interested in.

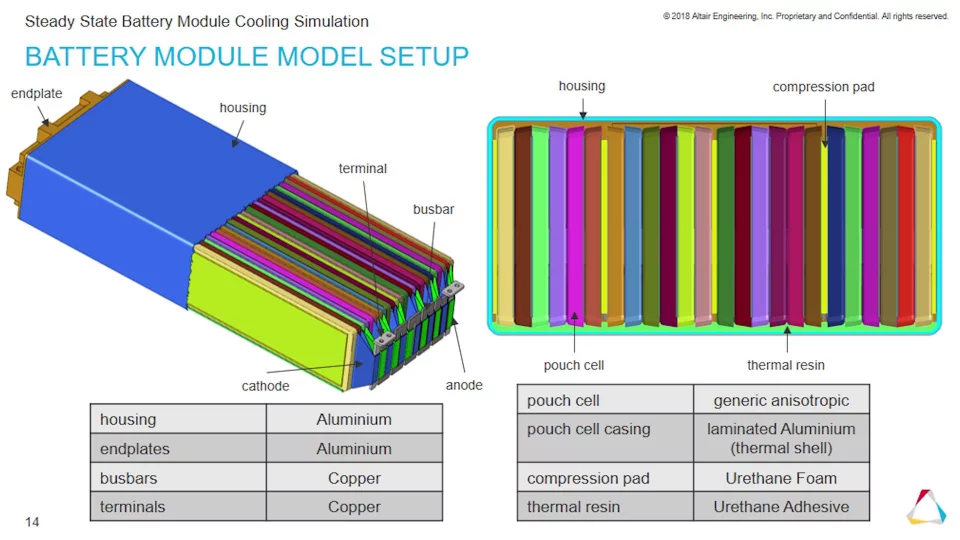

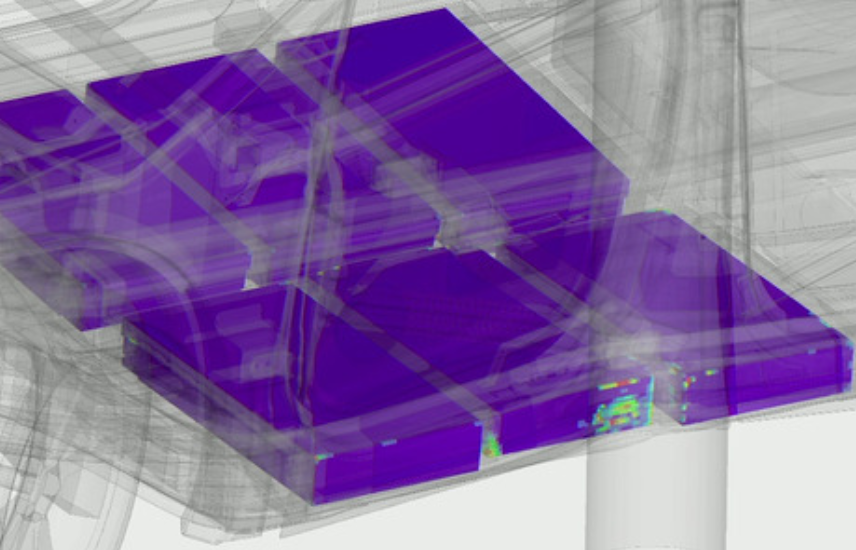

Simulation-based Design of a Traction Battery Cooling Plate

In this presentation, we will walk through the steps of early cooling plate design, using simulation to optimize pressure drop, coolant flow rates and general cooling performance as well as making first predictions on cell temperatures for different operating conditions and doing preliminary operational profile runs in preparation for a full vehicle simulation. We will also talk about model interfaces to other simulations tools and simulation disciplines, and how the model of cooling plate and battery can be expanded from a thermal model to a full multiphysics model.

Physics-based Cell and Pack Models for System Simulation

Sendyne, part of the Altair Partner Alliance, provides a virtual, physics-based battery model called CellMod Virtual Battery, which can be integrated into Altair Activate for system simulation.

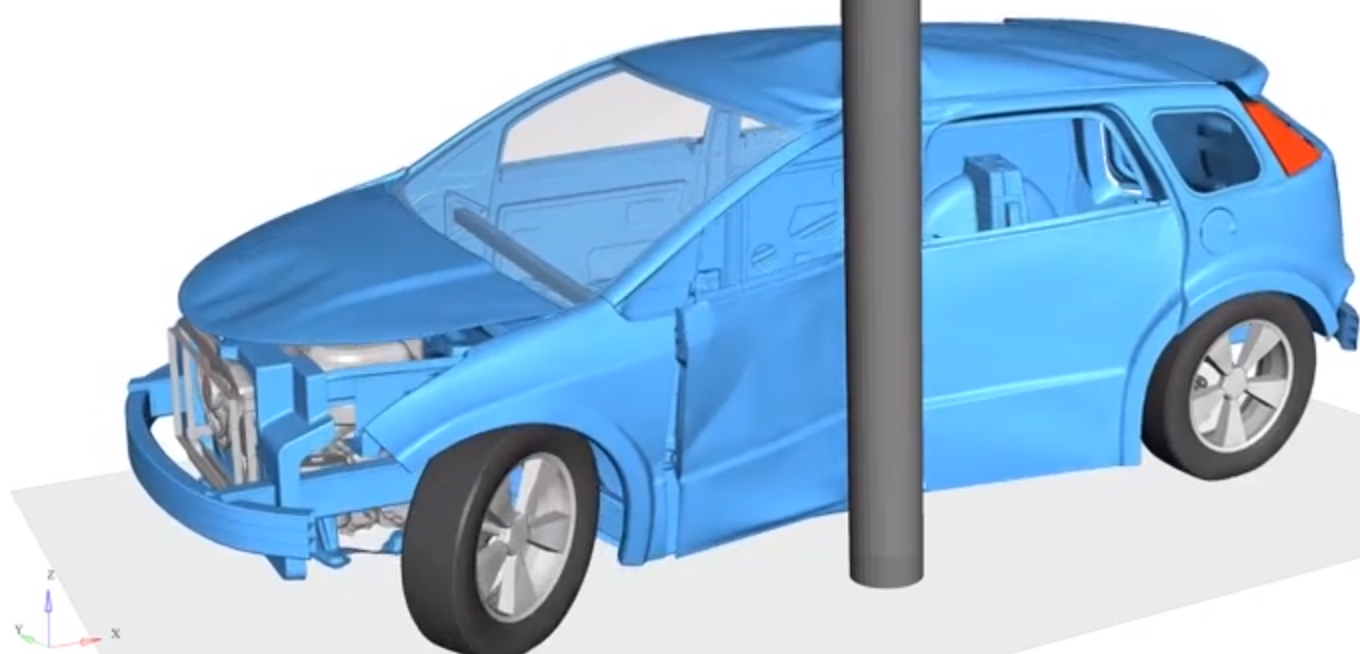

Modeling the Thermal Runaway Behavior of Li-ion Batteries upon Mechanical Abused Loading

This presentation demonstrates Altair’s capability of simulating the behavior of a mechanically damaged battery from a cell to a pack integrated in a vehicle, based on collaborative research previously conducted with MIT. An innovative approach of applying electromagnetics loss to predict rising temperature due to short circuit effects during an impact is discussed, along with the development of a software tool, Battery Design, which enables OEMs and suppliers to design battery applications using multiphysics optimization, including mechanical-electrical-electrochemical-thermal behaviors.

Address the Crashworthiness Challenges of Electric Vehicles using Simulation

Peter Snape, Crash Technical Specialist at Altair presents at the UK e-Mobility seminar 2019. Developing a 5-star EV (eg. Specific Legislation FMVSS305). Exploiting Crashworthiness Opportunities of EV Architectures.

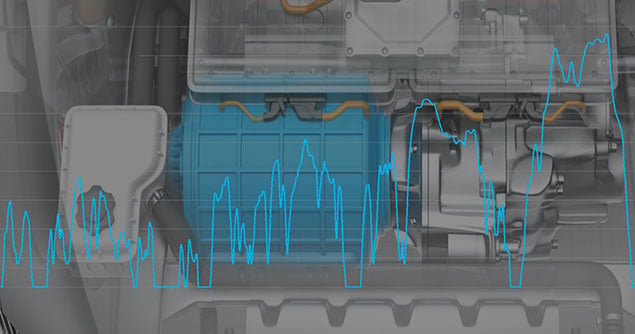

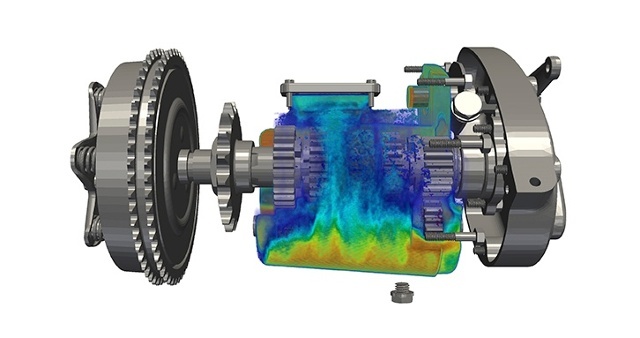

CFD Simulation for Electric Vehicle Powertrain Development

Gareth Lee, Senior CFD Specialist at Altair presents at the 2019 UK e-Mobility Seminar. How multiphase SPH can support cooling and lubrication system development. Improving powertrain efficiency and thermal management for better EV performance.

Overcoming e-Motor Thermal Load Challenges with Simulation

The presentation shows how CFD simulation helps to determine the thermal load of electric motors and how to develop the optimum cooling system for maximum performance and life time.

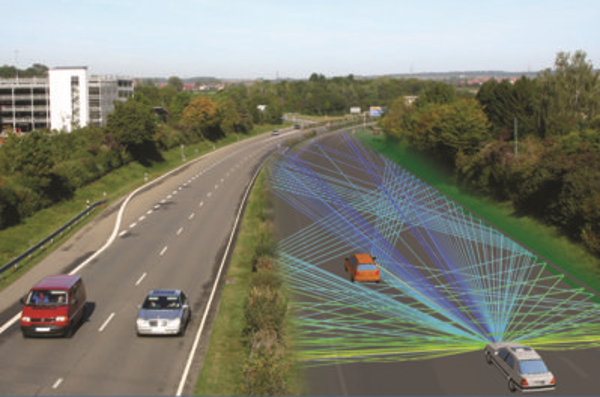

Virtual Drive Tests for ADAS Radar Sensors and Communication Antennas

This webinar shows how Altair WinProp considers the full environment including buildings, cars, street objects in order to get accurate representations of the radio waves impinging on the installed car antennas and the multipath radar channels including reflections, diffractions and scattered contributions. For the efficient analysis the car objects can be also replaced by their corresponding radar cross sections (pre-calculated in Altair Feko). Thus allowing the realistic and fully reproducible evaluations of different options for the antennas and sensors including their integration and configuration.

Using Machine Learning and Optimization to Develop e-Motor

The Altair Multiphysics platform provides a broad portfolio of solvers and tools to help engineers develop e-motor design requirements by using simulation and optimization methods. This presentation provides examples, using Altair Machine Learning and optimization solutions, of the e-motor requirements by leveraging in data available, which is key for e-motor designers to reduce time-to-market.