Terms of Use | Privacy Notice | Data Privacy Framework | Cookie Notice | DMCA | Whistleblowing |

© Altair Engineering Inc. All Rights Reserved.

Terms of Use | Privacy Notice | Data Privacy Framework | Cookie Notice | DMCA | Whistleblowing |

© Altair Engineering Inc. All Rights Reserved.

Altair at formnext

We help technology companies reach their full design and manufacturing potential to create advanced products and services.

Join us at the booth as we highlight the journey of traditional & advanced manufacturing from design to production. We will answer some of the your fundamental questions:

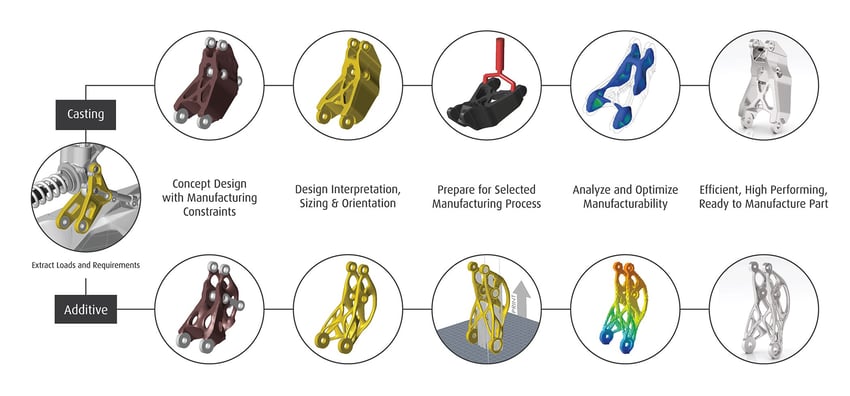

Simulation-Driven Design for Advanced Manufacturing

Challenge:

Motorbike rear suspension pivot is redesigned for better performance, higher efficiency, and part consolidation.

Assess and benchmark designs for different manufacturing processes.

Process:

Result:

Best performing parts economically manufactured.

Robot Customization

(WAAM and Generative Design)

Why customize an industrial robot? Industry robotics is a growing industry with a large variety of application classes. Many OEMs offer a wide variety of models for specialized applications. But there is a need for even more individualization.

Drone Structure

(Selective Laser Sintering Metal)

Chest Orthoses

(Selective Laser Sintering Polymer)

Combine 3D scanning with simulation of the human body to create highly customized 3D printing orthoses.

Read customer story to learn more!

Simulation-driven designed and pneumatically actuated robot with printed lightweight structures based on the EU funded research project DIMAP and PhD project of Gabriel Dämmer ©Festo AG & Co. KG

Read Blogpost to learn more!

Drive Designs and Improve Manufacturing Decisions with Machine Learning

Leverage machine learning in your advanced manufacturing initiatives to improve the overall performance from design to production.

Machine learning is used by organizations to ensure that early design direction aligns with part yield, repeatability, cycle time, production planning goals and reduced costs.

Predict production performance based on specific conditions to avoid unplanned downtime on devices and enable predictive maintenance. Enable your organization to make real-time assessment and predictions with end-to-end analytic processes from data preparation over Predictive Analytics to the deployment of data models in valuable visualizations.

Visit our booth to learn more!