The Science of Possibility

Hannover Messe 2024 Altair Media Kit

When Data Science Meets Rocket Science, Great Innovation Happens

Altair leverages computational science to drive innovation and intelligent decisions for a more connected, safe, and sustainable future.

Industry experts frequently highlight key challenges and priorities, including achieving success in Digital Transformation through the integration of AI and machine learning in both product development and manufacturing processes. Additionally, there is a consistent emphasis on the imperative for time and cost reduction in product development. Lastly, sustainability and energy efficiency emerge as crucial focal points in industry discussions, reflecting a growing awareness of environmental concerns and the need for responsible business practices.

For nearly 40 years, our entrepreneurial spirit and technical expertise have fueled our and our customer’s growth by seeking technology and business firsts. We support and empower 13,000+ customers globally to address these challenges and to compete more effectively in a connected world, all while creating a more sustainable future.

At Hannover Messe 2024 Altair presented technologies, methods, and examples of how companies can succeed with their quest for digital transformation by applying simulation, data analytics, Artificial Intelligence, and High-Performance Computing. During the Event, as well as on this Landing Page and in the attached Media Kit, we will showcase innovative solutions encompassing Simulation-Driven Design, AI-Powered Engineering, Digital Twins, and the integration of AI on the Factory Floor.

You couldn't make it or would like to know more? Request an Altair customer or expert interview.

Learn more about Altair, read past PRs and the Media Lunch presentation

Download Media Kit

Simulation-Driven Design

Despite FEM software being commercially available for half a century, the key bottleneck in development is still the transformation of a CAD design into a simulation model!

Our unique technology enables designers and engineers to integrate simulation into the design process, informing the direction from the beginning and achieving performance targets quickly. Altair SimSolid revolutionizes simulation for designers, engineers, and analysts by eliminating time-consuming tasks like geometry preparation and meshing. Altair Inspire accelerates simulation-driven design, reducing time-to-market and enabling the creation of high-performance designs. Altair's simulation-driven design offers a smarter approach to electronics product development, delivering innovation at lower cost.

Additional Resources Available in the Media Kit

Fighting Fire with Innovation

Austria's SYNEX TECH GmbH, a special machinery firm, collaborated with M&H CNC Technik to create DRILL-X, the world's first fire extinguishing device merging drilling and extinguishing. Using Altair® Inspire™, they optimized design and manufacturing, employing additive manufacturing for efficient production. Altair technology streamlined prototype and series production, cutting development and additive manufacturing costs by minimizing material usage, print times, and post-processing effort.

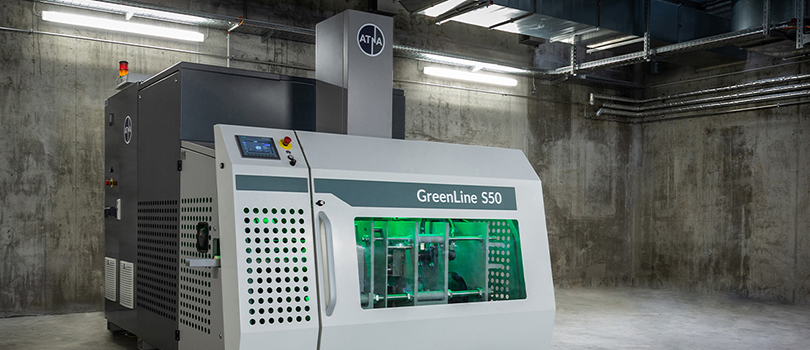

Simulation Under High Pressure

By acting flexibly and driving innovation, mechanical engineering has taken up the challenges of recent times. In this context, often the startups enrich the sector with innovative ideas and leverage digitization for their revolutionary machine designs. ATNA Industrial Solutions GmbH has accelerated the design and development process of its novel hydraulic press with the help of a new simulation tool, thus achieving its ambitious development goals.

Samsung SDI Improves PCB Development

Samsung SDI faced challenges transitioning to the electronic materials business, requiring a new approach to PCB designs and manufacturing. They evaluated Altair PollEx for centrally managed PCB design review and verification, streamlining the process and saving an estimated $6 million annually. PollEx is also used to detect manufacturing faults and electrical failures, with future plans for signal, power, and thermal analysis using PollEx Solvers.

AI-Powered Engineering

As the pace of innovation accelerates, the use of AI and machine learning is becoming standard practice. Altair, a leader in generative design and AI, enables teams to discover actionable insights, speed design, and accelerate product development.

Altair® physicsAI™, Altair® expertAI™, Altair® shapeAI™, and Altair® romAI™ unlock limitless potential for gaining insights, accelerating predictions, and improving engineering decisions. With seamless integration into the Altair® HyperWorks® platform, they deliver unparalleled AI-powered engineering capabilities.

Digital Twins - Overcome Industry Bottlenecks in Product Development

Model Building Process

Altair's digital twin solutions and technology like romAI enable the industry to build digital behavior models faster and:

- Run models faster

- Avoid co-simulation to capture high-fidelity behavior

- Accelerate system models by 1,000x while maintaining accuracy

The following examples will be presented: Danecca; Gruppo Cimbali; Patrone and Mongiello; Leonardo

Pattern identification and optimization

Based on the result fields of many simulated design variants, a group with uniform behavioral patterns is created using unsupervised learning, a machine learning approach. This allows hundreds of simulations to be processed intuitively. The example of megacasting impressively demonstrates the advantage AI over traditional methods.

Setting Sail with Digital Twins

The America’s Cup is the oldest and most respected sailing competition worldwide, first held in 1851. Team Luna Rossa Prada Pirelli, who has participated in five prior AC competitions, will be competing in the 37th America’s Cup in Barcelona from August to October 2024. They have experience with Altair solutions, using the full spectrum of Altair’s technologies in the upcoming AC37 to ensure the best results, with a strong focus on structural simulation and HPC.

/Altair_Trends_Frictionless-AI-ML_Hero.png?width=1920&height=450&name=Altair_Trends_Frictionless-AI-ML_Hero.png)

AI on the Factory Floor

Today, most companies want to invest in data analytics and AI, but recent data shows that only 13% of all companies excel at delivering on their data strategy. The reasons for this vary from company to company. To learn more, check out the linked report above.

With Altair’s data analytics solutions, you can scale AI initiatives without requiring a big team of data scientists or expensive service engagements. Upskill your workforce so users from novice and expert users alike can leverage the data and analytics tools needed to provide data-driven insights.

Enhance Supply Chain Management

Inefficiencies, delays, and higher costs are just some of the challenges the manufacturing supply chain faces today. Altair understands these challenges and provides comprehensive supply chain management solutions to optimize sourcing, inventory, and logistics. Our tools, including supplier collaboration, demand planning, and logistics optimization, help customers enhance efficiency and cost savings.

With Altair’s data analytics and supply chain optimization expertise, manufacturers can master variable demand and streamline their operations, ensuring they can deliver high-quality products to their customers on time and within budget.

Plan Maintenance and Prevent Equipment Failure

Conducting preventative maintenance, according to use time and cycles, helps all industries avoid equipment failure. But it can also mean stopping a well-functioning machine even if there’s nothing currently wrong. Predictive maintenance is a better way an organization can maintain equipment without disrupting production.

By pairing our intuitive machine learning tools with cloud-based or edge computing systems to analyze data from your factory floor, Altair® RapidMiner® - Altair’s data analytics and AI platform – helps you keep a close eye on your equipment’s health. Our solutions give you the confidence to keep machines running, knowing that you can catch and address issues that aren’t easily detectable, avoiding costly failures and equipment downtime.

Transform the Warranty Process

The sheer number and variety of warranty claims in the automotive market makes traditional business intelligence-based methods unwieldy. But these claims contain valuable information about product quality and reliability, and customer expectations, and can also reveal design or manufacturing defects. Our solutions enable automakers to utilize this data source to improve existing products, develop more reliable new products, and increase profitability.

/altair_trend_electrification_hero.jpg)