Enabling Accelerated Development of Electric Vehicles

Join our Altair Partner Alliance electric vehicle webinar series!

Battery Modeling and Dynamic Simulation for Electric Vehicles

Featuring MapleSim by Maplesoft

As oil prices rise, there is an increased focus on developing high efficiency, cost-effective electric vehicles whose performance will be competitive with gas-powered cars. The automotive industry is turning to virtual prototyping for vehicle development to significantly reduce development times and costs, and so it is essential that they have efficient, high-fidelity battery models as part of their electric vehicle development.

MapleSim allows you to incorporate realistic physics-based models of battery cells into your multidomain system-level models. This webinar covers new approaches to modeling and simulation of EVs and HEVs. Learn about the MapleSim and see how system-level modeling can be used to create high-fidelity EV and HEV models.

Presenter: Graham Jackson | Engineering Specialist, MapleSoft

The Fundamentals of Designing Electric Powertrains Using ChassisSim

Featuring ChassisSim by ChassisSim Technologies

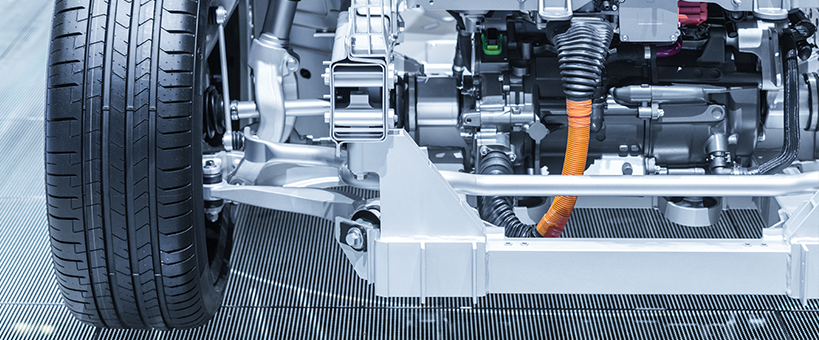

As Electric Vehicles become an increasingly important part of the automotive landscape their fundamentals and application is not well understood. This webinar will show you the basics of how an Electric powertrain works, how to do a basic specification and applying this using the Electric Powertrain module in ChassisSim.

Presenter: Danny Nowlan | Director ChassisSim Technologies, ChassisSim Technologies

Integration of Requirements Management with Electric Motor Design

Featuring ModelCenter by Phoenix Integration

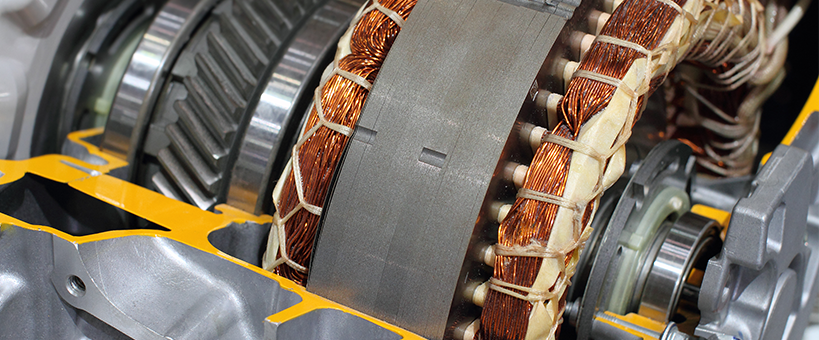

Phoenix Integration is a recently added member of the Altair Partner Alliance. Its product ModelCenter can create complex, fully automated simulation workflows and link these against Model Based Systems Engineering (MBSE) models. These typically descriptive models can now include accurate prediction of the system performance. This also means that the status of the system requirements can be verified early in the product design cycle, helping to avoid costly mistakes. Using ModelCenter, the systems engineer can explore the possible design options and choose a configuration that represents best value while meeting its requirements. This webinar will explore the application of this approach to a multidisciplinary Electric Motor design problem implemented using Flux (EMAG) tools from Altair.

Presenter: Ilya Tolchinsky | Lead Application Engineer, Phoenix Integration

Battery Performance, Lifetime, and Safety

Featuring TAITherm by ThermoAnalytics

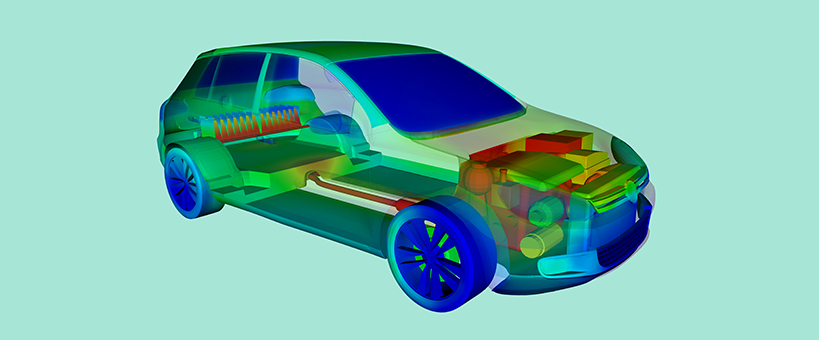

As battery technologies advance and consumers expect extended range and shorter charge times, using transient thermal simulation to predict battery performance has become increasingly crucial. Join us as we demonstrate how you can leverage TAITherm software and Battery Extension to accurately predict battery performance, lifetime, and safety in a wide range of real-world environmental conditions.

We will show you how to simulate different usage scenarios, and how heat produced by the battery can lead to failure including thermal runaway. We will take you inside TAITherm software while exploring case studies and examples of past results.

Presenter: Zachary J. Edel, Ph.D. | Senior Research Engineer, ThermoAnalytics

Using Finite Element Models Beyond Their Upper Frequency Limits in Electric Vehicle Applications

Featuring EFEA by Michigan Engineering Services

A hybrid finite element formulation that extends the applicability of finite element models to higher frequencies will be discussed. It is based on reducing the size of the finite element model significantly by replacing major parts of the model with equivalent dynamic impedances during the finite element calculations. The Component Mode Synthesis (CMS) approach is combined with analytical solutions of dynamic and static modes for computing appropriate values for the dynamic impedances. The power dissipated by the dynamic impedance elements provides the link to an energy finite element model of the omitted parts for computing their response. Theoretical aspects, the functionality of the implementation, and comparisons between simulations and experiments for production automotive and rotorcraft systems will be presented.

Presenter: Nick Vlahopoulos | CTO, Michigan Engineering Services