Privacy Notice | Terms of Use | Cookie Statement | DMCA | Whistleblowing |

© Altair Engineering Inc. All Rights Reserved.

Privacy Notice | Terms of Use | Cookie Statement | DMCA | Whistleblowing |

© Altair Engineering Inc. All Rights Reserved.

Lillestrøm (Oslo), Norway

June 11-15, 2018 | Booth #708

Altair transforms design and decision making by applying simulation, machine learning, and optimization throughout product lifecycles.

Come experience the technology and simulation-driven design processes that are radically changing the way the aerospace and energy sectors innovate!

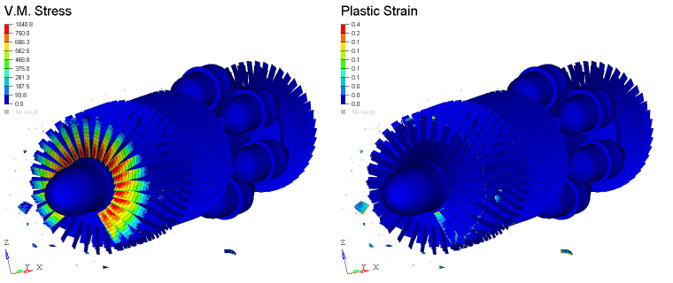

Altair and GE have signed a multi-year software agreement making Altair the exclusive distributor of GE’s Flow Simulator software. Flow Simulator is an integrated heat transfer, combustion, and fluid design software that enables improved system integration to optimize machine design.

Experts from Altair and GE will be demonstrating Flow Simulator's single fluid system modelling capabilities and their applicability to turbomachinery design.

Strap on a pair of VR goggles and enter an immersive experience exploring a turbine and seeing how simulation technology helps save development time and optimize performance. The VR experience will give a first-hand look at Altair's simulation driven design process.

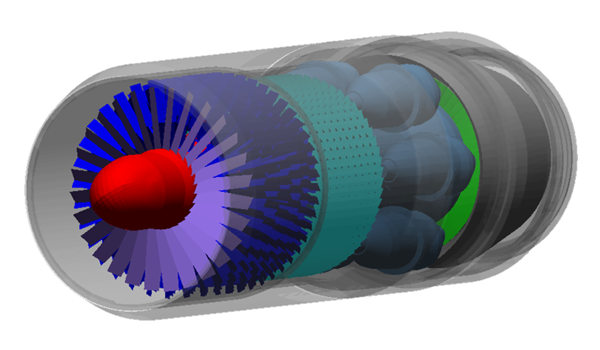

Lattice 3D Printed Turbine Nozzle

Using optimized lattice structures developed in OptiStruct, this ALM printed turbine nozzle reduces material use, saves weight and delivers increased performance and product service time.

Automated Meshing Process on Complex 3D Printed Parts using Simlab

3D printing allows for increasingly complex cooling passages in even tighter packaging spaces. Watch how Simlab facilitates generating a high quality mesh on complex geometry parts with very thin regions within a complex solid.

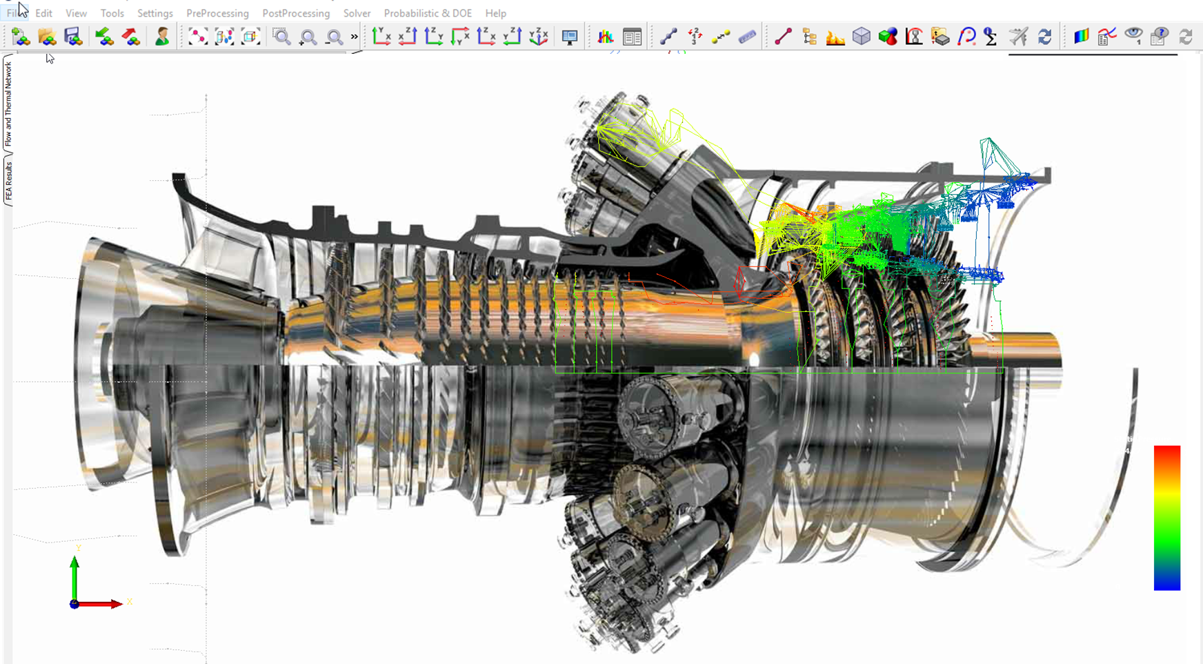

GE's Flow Simulator model of a GE gas turbine