Terms of Use | Privacy Notice | Data Privacy Framework | Cookie Notice | DMCA | Whistleblowing |

© Altair Engineering Inc. All Rights Reserved.

Terms of Use | Privacy Notice | Data Privacy Framework | Cookie Notice | DMCA | Whistleblowing |

© Altair Engineering Inc. All Rights Reserved.

The concept development phase of an automotive ‘body-in-white’ structure is characterized by the availability of design freedom to experiment with different packaging, manufacturing and structural strategies. This rapid exploration of different ideas helps to inject innovation into the platform design. However, traditional simulation (CAE) often isn’t quick enough to deliver the required design direction.

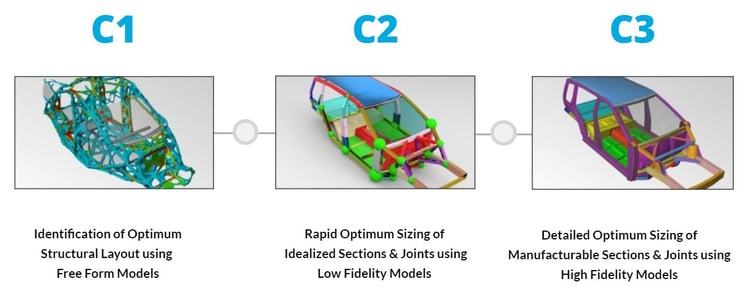

To meet this challenge, Altair has developed a unique three stage concept development process, C123. Every stage deploys optimization technology, providing the designer with structural data relating to the mass and attribute performance consequences of various design decisions and facilitating target ‘trade-offs’. Throughout the process, the sophistication of simulation technology is matched against the maturity of the available design data in order to ensure simulation is a collaborative partner in the design process.

C123 is independent of vehicle architectures (e.g. monocoque, body-on-frame, tub and spaceframe etc.), manufacture process (e.g. extrusions, sheet metal, casings etc.), material selection (e.g. metals, composites, mixed etc.) and platform sharing strategy. The process is supported by a bespoke toolbox built off Altair HyperWorks. It has strong interoperability with CAD to ensure optimised structural architectures can be efficiently incorporated into the design environment.

Learn more about C123 through series of video interviews with leading practitioners, Dr. Royston Jones and Dr. Stuart Bates.

Dr. Royston Jones & Dr. Stuart Bates

discuss the C123 process.

What are the concept challenges?

How does C123 meet these concept challenges?

Where can C123 be applied?

What is the implementation strategy for C123?

How does C123 deliver to the required timescales?

C123 in Summary

If you have a question about C123 or would like to discuss the process further, please complete the form below and we'll contact you.