Driving designs cognizant of the downstream manufacturing processes

Utilizing Altair's user-friendly and affordable simulation software, users are able to validate designs early in the manufacturing and design process.

Showcasing simulation tools to optimize the entire manufacturing process for casting, additive manufacturing, sheet metal forming, metal and polymer extrusion and more. Utilizing Altair's user-friendly and affordable simulation software, users are able to validate designs early in the manufacturing and design process.

Optimize the entire manufacturing process

On-Demand

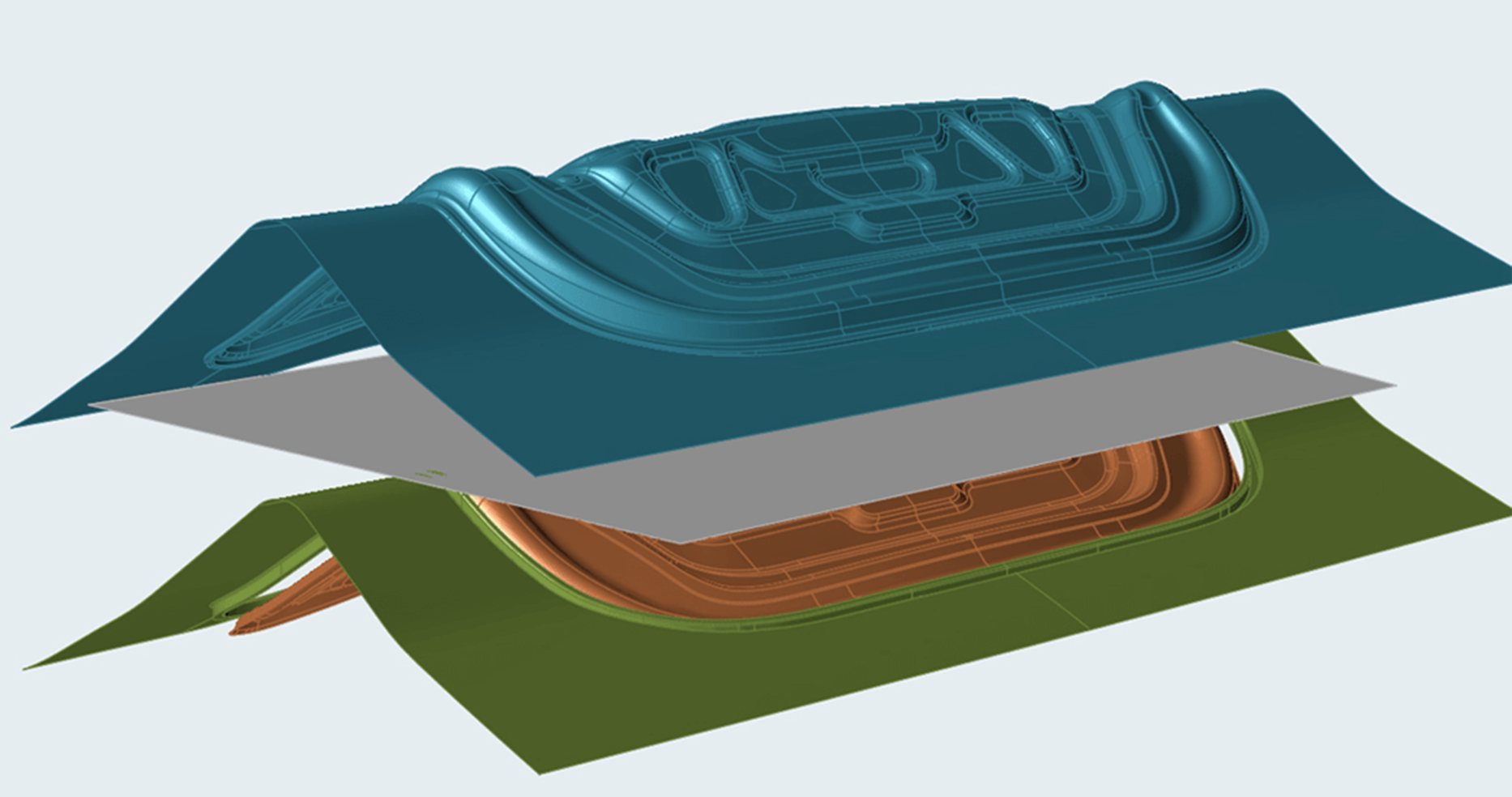

Simulation Driven Design for Casting Parts and Process Design

Find out about the benefits of introducing manufacturing simulation software early in the design process. During this session, we will explain why Altair Inspire Cast makes your designs more reliable, optimized and accurate.

New designs in combination with new materials demand designers to evaluate their designs early. As the process gets refined the ability to further investigate and optimize the process makes Altair Inspire Cast uniquely valuable during the entire product development cycle from early design to manufacturing.

On-Demand

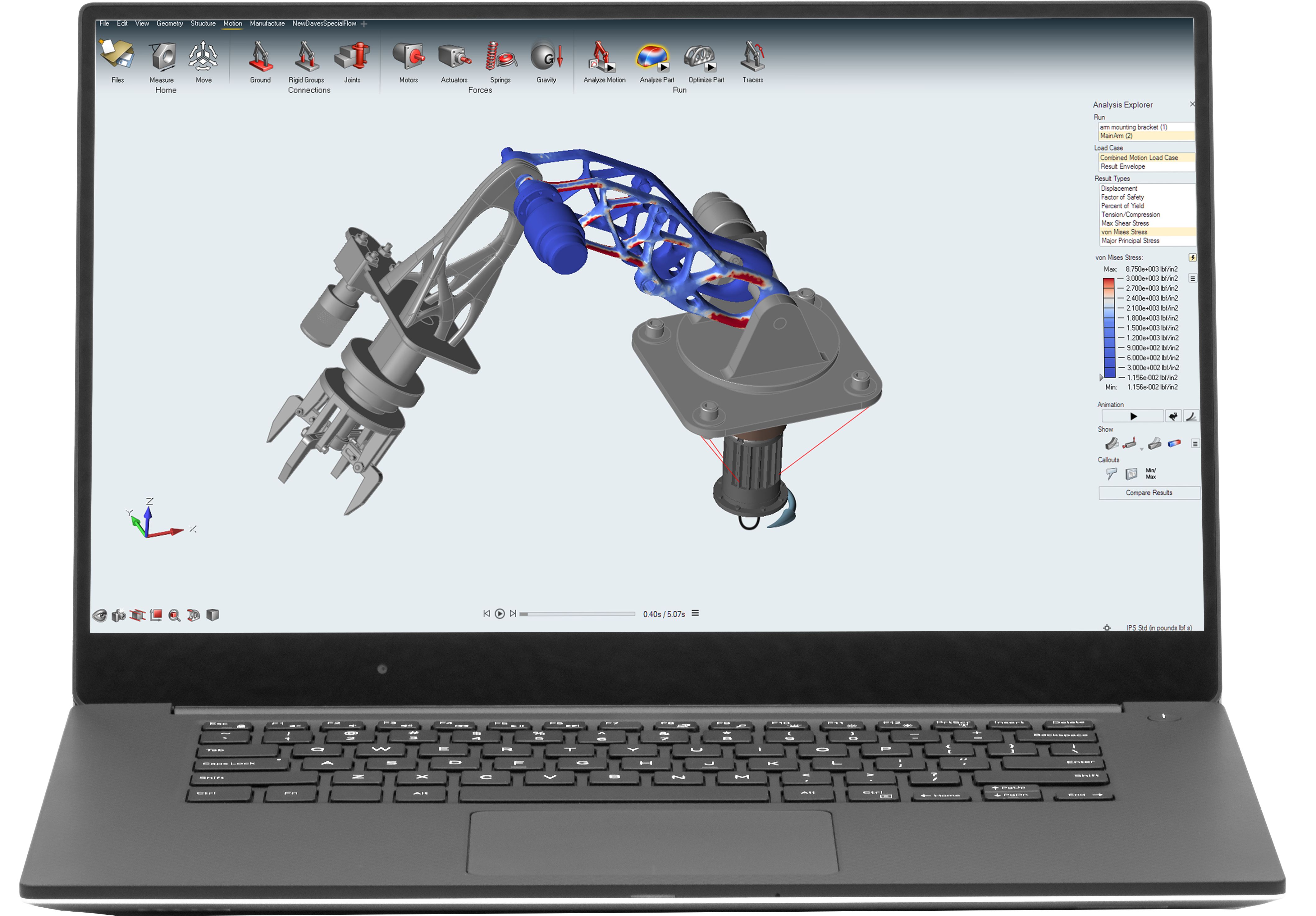

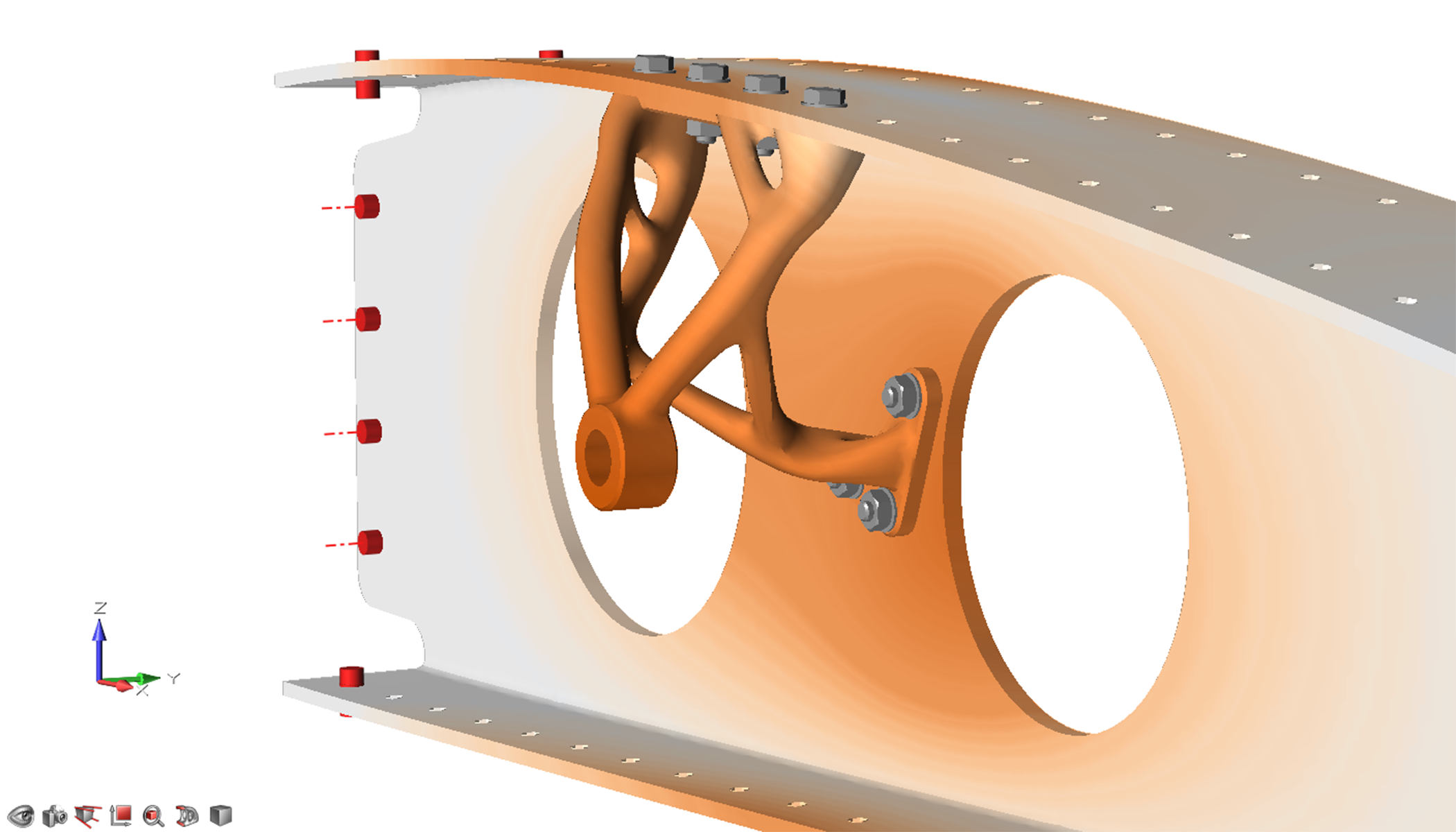

Design for Additive Manufacturing Using Topology Optimization

Learn how companies are increasing functionality while decreasing costs by combining design optimization and advanced additive manufacturing technologies. During this session, we will explain why Altair Inspire makes your designs more reliable, optimized and accurate.

Topology optimization and generative design software further exploit the benefits and capacity of additive manufacturing by generating designs that increase function and reduce material, weight, design time, and cost.

On-Demand

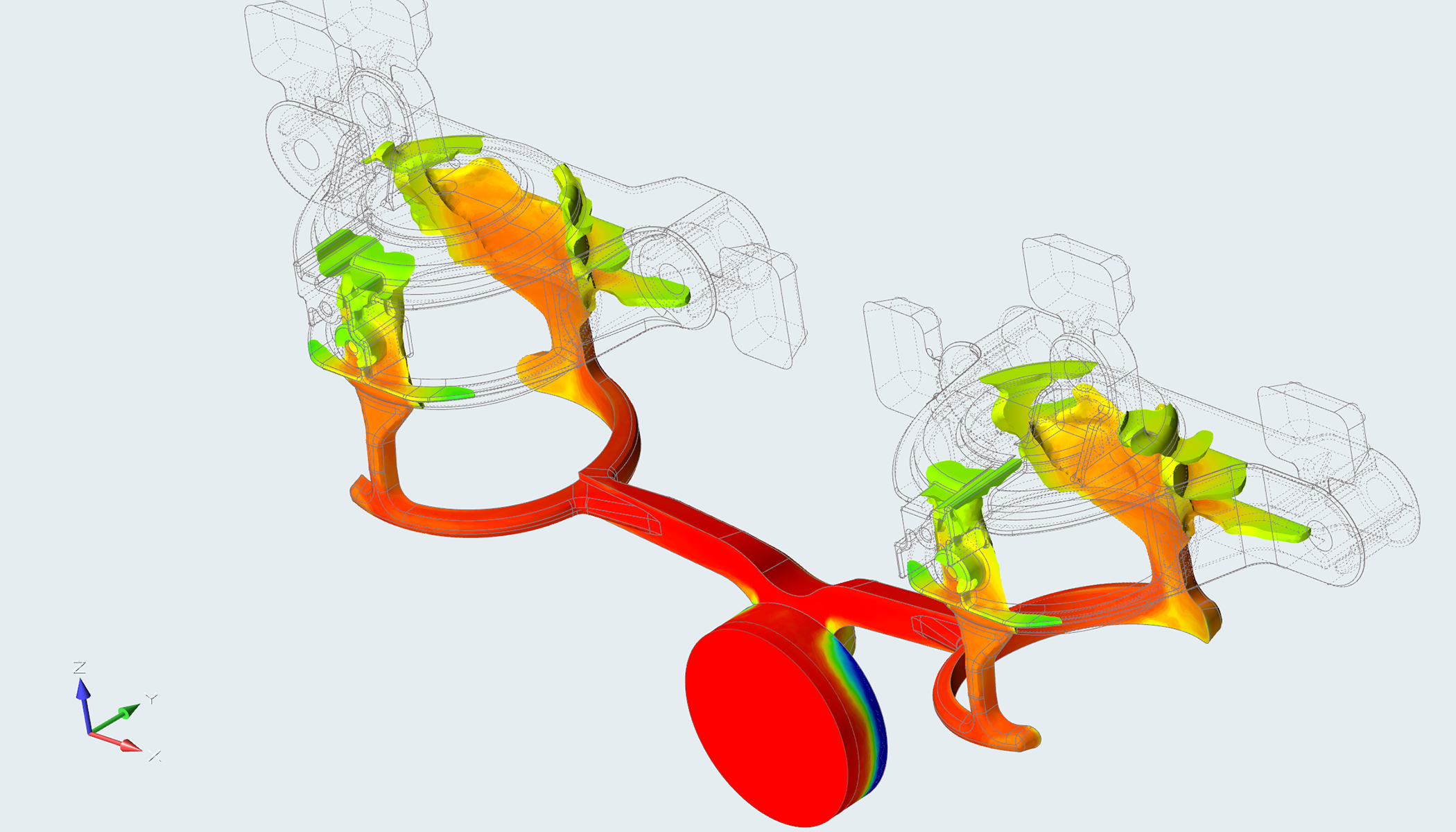

Simulation of Multi-Stage Stamping Process Fully Automated and Highly Scalable without Sacrificing Accuracy

With recent advances in simulation technology and cloud computing, enormous opportunities are emerging to design lighter products with superior performance and manufacturability. High cost associated with advanced high strength and special materials requires up-front assessment of manufacturability and material utilization, simultaneously keeping focus on structural performance and assembly requirements.

Industry experts will present:

On-Demand

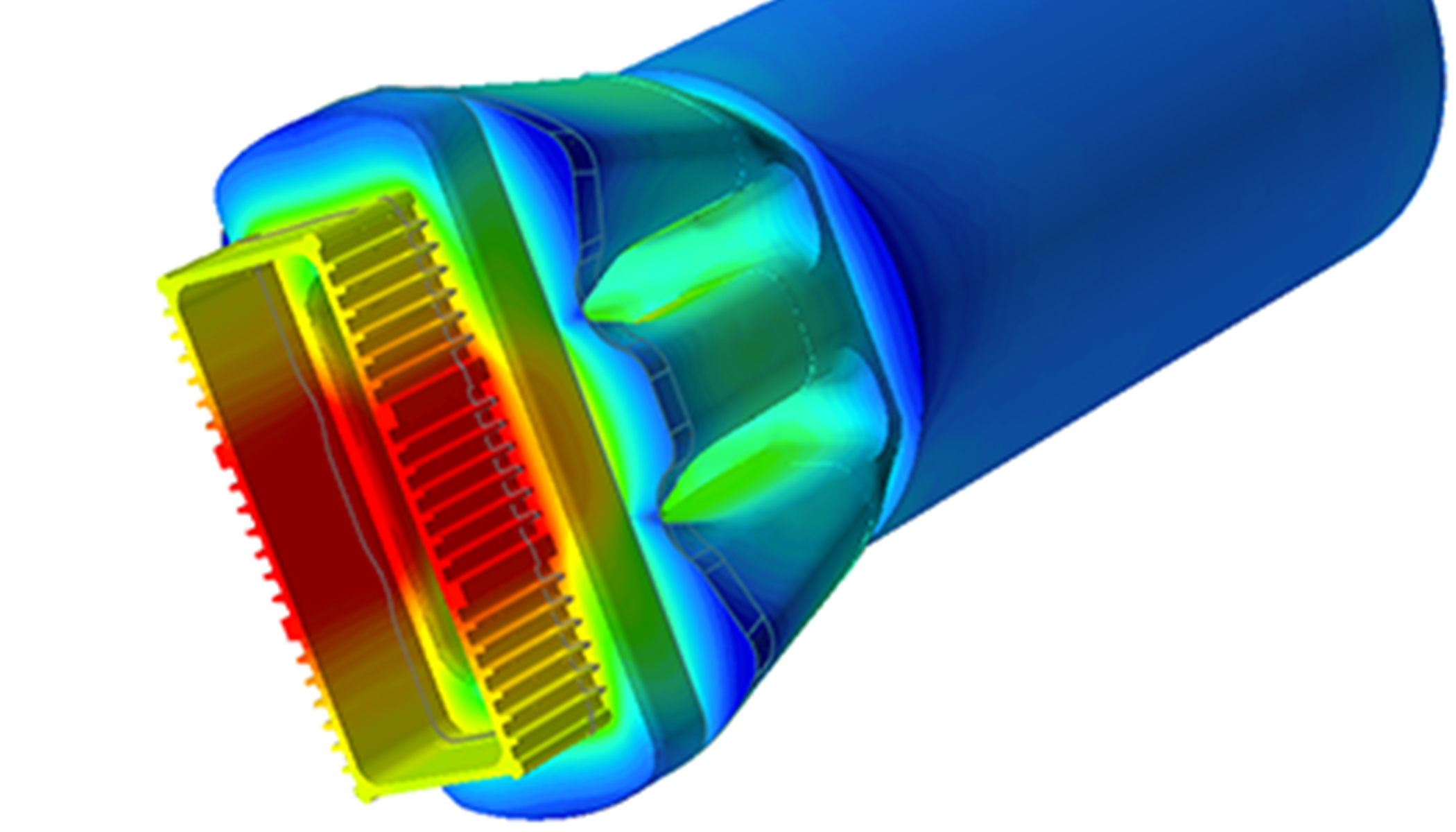

Streamlined Metal and Polymer Extrusion Simulation

Increasing manufacturing costs and stiff completion coupled with low profit margins are posing tremendous challenges to extrusion companies, especially automotive and aerospace industries. One way the leading companies stay ahead of the competition is by reducing the product development time and production costs through virtual testing. Design engineers and analysts use CAE software to analyze and validate die designs and thereby reduce/eliminate costly die trials.

This webinar explains how extrusion simulation framework provides an easy to use CAE environment to: