Technical Webinar: Pharmaceutical Powder Process Modeling using the Discrete Element Method (DEM)

Live Webinar: Tuesday, October 20 | 7.30 pm IST

Powders are at the core of the pharmaceutical manufacturing process and their variable physical characteristics and flow properties present unique challenges to industry. Powders are opaque and it is difficult to visualize and understand their behavior using experiments alone.

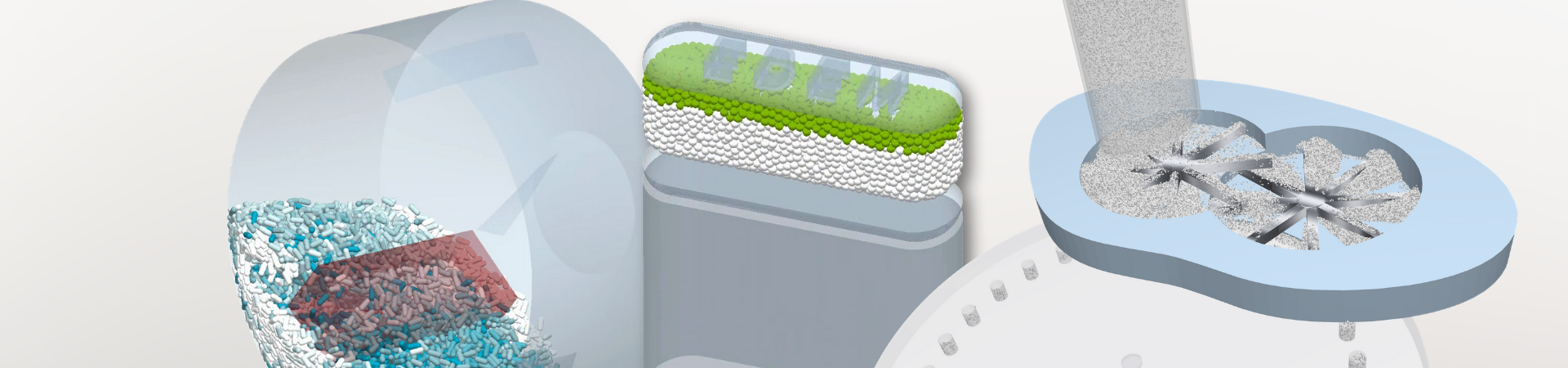

The Discrete Element Method (DEM) is a numerical method that captures the complex macro-mechanical behavior of a wide range of granular solids, including powders, for a wide range of process and operational conditions. DEM provides key insight into operations and processes otherwise difficult or impossible to obtain using experiments. It is proven to be a valuable predictive tool for simulating pharmaceutical manufacturing processes including powder mixing, coating, die filling, granulation, milling and more.

In this technical webinar hosted in collaboration with the Center for Structured Organic Particulate Systems (C-SOPS) at Rutgers University, experts will discuss how DEM can be used to better understand powders and optimize pharmaceutical manufacturing processes.

The focus will be on 3 main questions and areas:

- What is the residence time distribution of particle blends?

- How to study powder properties changes due to shear?

- How to approach DEM calibration and material databases?

Presentations will also cover examples of applications of Altair EDEM software and techniques for calibrating powders.

AGENDA

Each presentation will be followed by a 10 minutes Q&A session.

|

Time (EDT) |

Topic |

|

07:30 - 07:45 pm |

Overview of the Center for Structured Organic Particulate System (CSOPS) and collaboration with Industry |

|

07:45 - 07:55 pm |

Calibration of powder materials & optimization of powder handling processes using Altair EDEM |

|

07:55 - 08:25 pm |

Residence Time Distribution (RTD), How Is It Affected by The Material Properties |

|

08:25 - 08:50 pm |

Shear and Material Properties - Lubrication, Silication, Attrition, Electrostatics and Agglomeration |

|

08:50 - 09:00 pm |

Wrap-up and Q&A |

WHO SHOULD ATTEND?

Engineers, scientists and researchers involved in the drug product manufacturing process.

Anyone interested to learn more about deploying the Discrete Element Method to optimize drug development.

Speakers

|

Dr. Fernando J. Muzzio Fernando Muzzio is a Distinguished Professor of Chemical Engineering at Rutgers University. For the last 27 years, pharmaceutical product and process design has been Professor Muzzio’s main research and educational focus. His research interests comprise continuous manufacturing, pharmaceutical formulation, powder mixing, powder flow, segregation, compression, mixing and flow of liquids and suspensions, capsule filling, tablet dissolution, and tablet coating. |

Dr. Gerardo Callegari Dr. Gerardo Callegari, is an Associate Research Professor at CSOPS (Center for Structured Organic Particulate System) and the Department of Mechanical and Aerospace Engineering at Rutgers University. His background is in porous material- liquid interactions, where he has developed numerous characterization techniques. In the last eight years, Prof Callegari has been working on characterizing powder manufacturing processes in relation with powder material properties. Specifically his research focused on developing methodologies to identify failure modes and critical process parameters of direct compaction lines, advancing predictive methodologies to assess product critical quality attributes. |

|

Dr. Marina Sousani Dr Marina Sousani holds a BSc and a MEng degree in Civil & Structural Engineering and a PhD in Discrete Element Modelling (DEM) from Leeds University. Marina is a senior Research and Development Engineer and has over 6 years’ experience modelling granular material using DEM and various experimental methods. She joined Altair in 2016 and her role involves the modelling of complex applications using EDEM. She also manages a number of research projects in collaboration with leading Institutes in order to implement the latest scientific advances in the EDEM software. |

Optimizing Pharmaceutical Manufacturing Processes with EDEM Particle Simulation

Efficient handling and processing of particulates is critical to profitable manufactue of pharmaceutical products. Over 75% of all pharmaceutical products are in thesolid dosage form and particulates are involved in almost every stage of the manufacturing process.

Altair EDEM software - powered by the Discrete Element Method (DEM) - accurately simulates and analyzes the behavior of granular materials such as powders, tablets and capsules. It is a powerful tool used to model common pharmaceutical manufacturing processes such as mixing, blending, granulation and tablet coating.

This technology can provide key insights leading to optimized processes and innovation in product design.