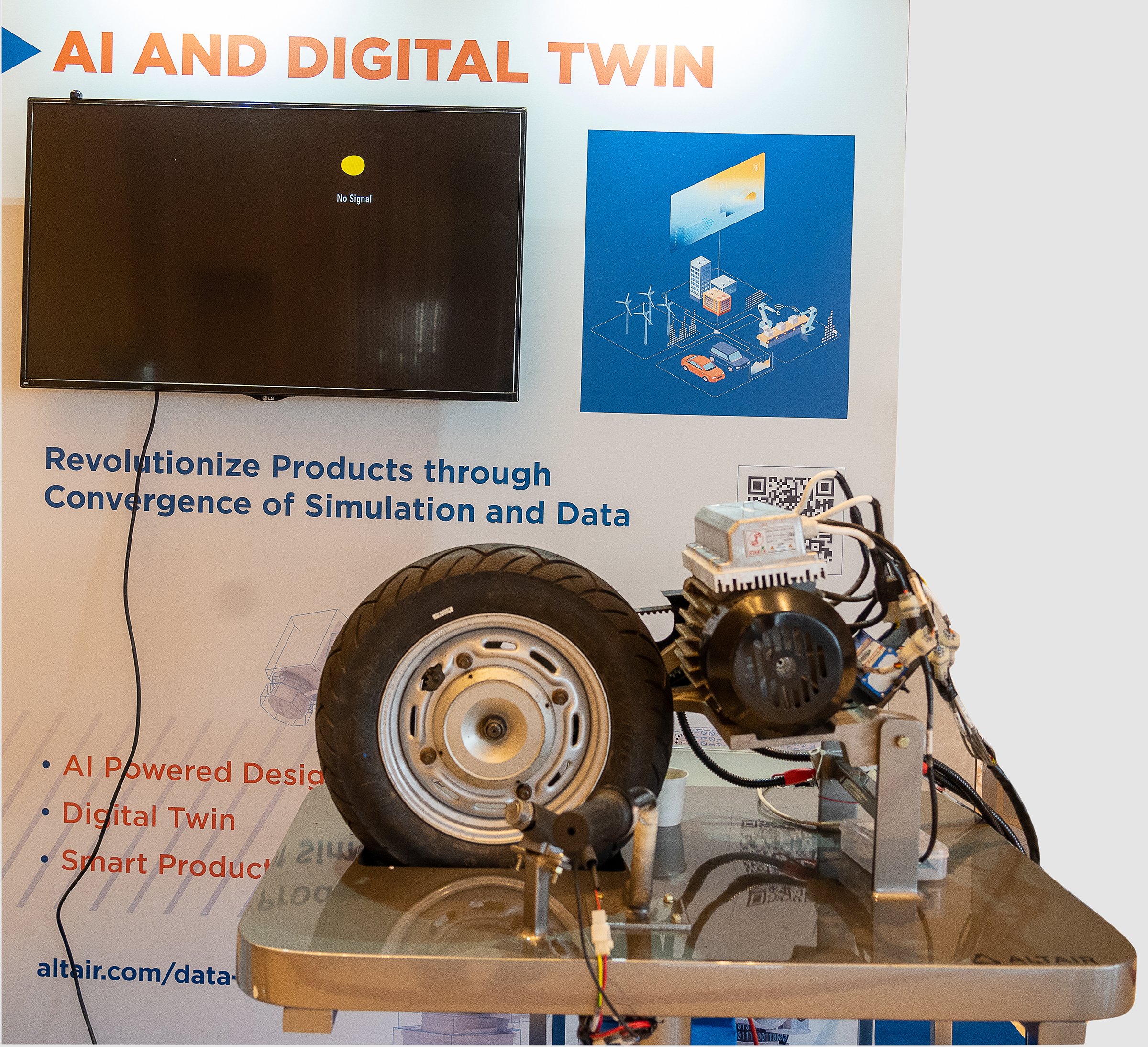

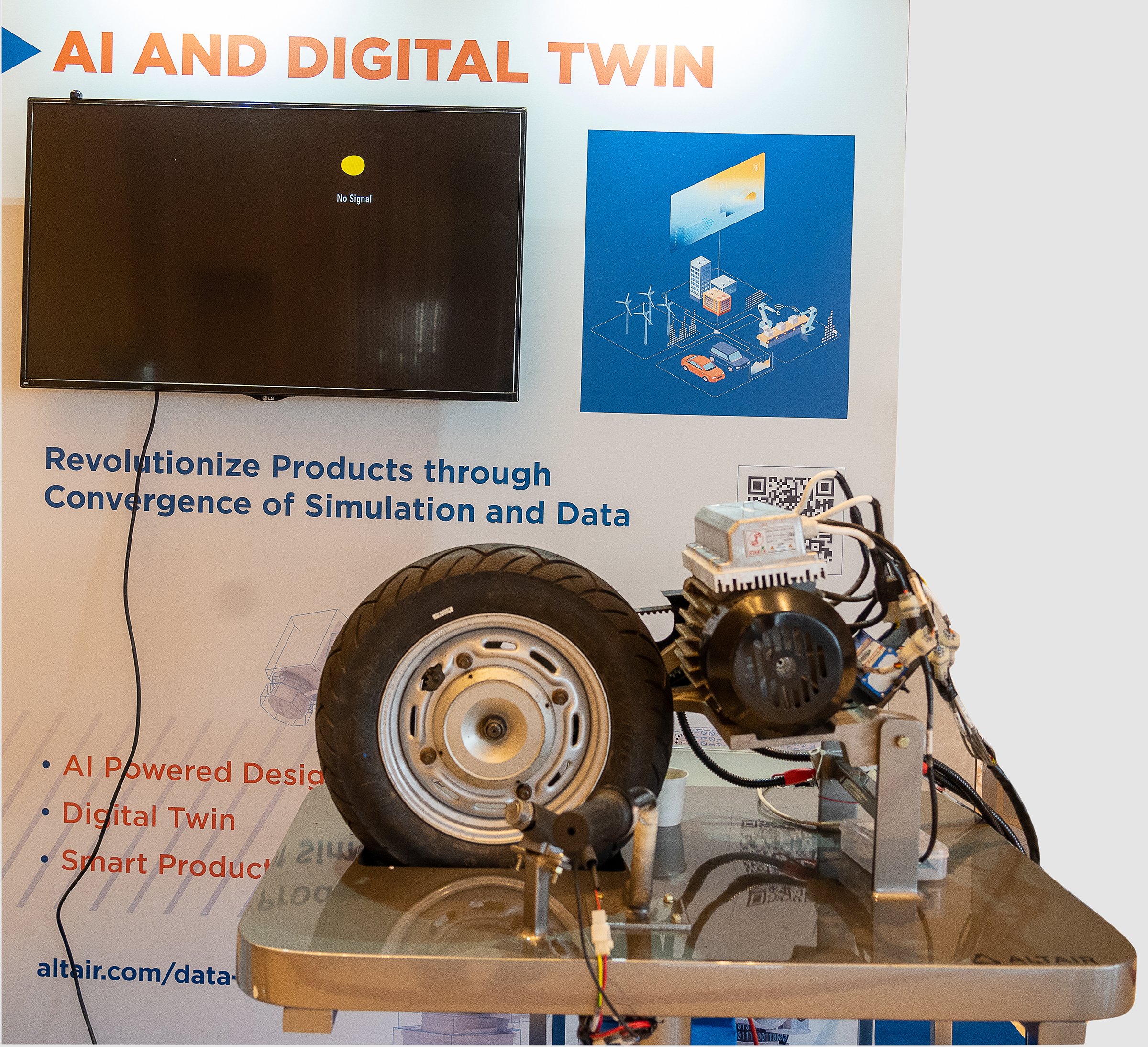

LEARN MORE WITH OUR DIGITAL TWIN DEMONSTRATOR

-May-25-2023-05-33-25-5847-AM.png?width=2317&name=MicrosoftTeams-image%20(7)-May-25-2023-05-33-25-5847-AM.png)

MEET OUR SPEAKER

.png?width=425&name=MicrosoftTeams-image%20(1).png)

Terms of Use | Privacy Notice | Data Privacy Framework | Cookie Statement | DMCA | Whistleblowing |

© Altair Engineering Inc. All Rights Reserved.

JOIN US AT ET AUTOTECH SUMMIT 2023

Enhancing Automotive Product Development with One Total Digital Twin.

-May-24-2023-11-13-59-7481-AM.png?width=365&height=95&name=MicrosoftTeams-image%20(2)-May-24-2023-11-13-59-7481-AM.png)

In the automotive industry, a digital twin is a virtual representation of a physical vehicle or a specific component throughout its entire lifecycle, from design and development to production, operation, and maintenance. It incorporates real-time data and simulations to enhance the product development process and optimize vehicle performance.

Visit us at booth #R5-R6, next to the coffee station.

Key takeaways at the booth

-May-25-2023-05-33-25-5847-AM.png?width=2317&name=MicrosoftTeams-image%20(7)-May-25-2023-05-33-25-5847-AM.png)

Vishwanath Rao, as Managing Director, drives and evolves Altair’s business and operations across South Asia & GCC countries while nurturing a strong leadership team to drive its growth. Mr. Rao manages regional strategy, client relationship management, and technical and sales effectiveness to ensure Altair’s exceptional growth..

.png?width=425&name=MicrosoftTeams-image%20(1).png)

Experience this enlightening conversation with Selcuk Sever, Principal Engineer at Switch Mobility, as we delve into the company's collaboration with Altair to elevate the accuracy of range estimation for their electric buses. Through this partnership, Switch Mobility endeavors to instill confidence in its public transport authority customers by providing precise predictions of the electric buses' range, thereby ensuring their ability to meet the unique demands of diverse bus routes. Prepare to be captivated by this engaging dialogue!

At the core of our digital twin integration platform are our flexible, agile, and vendor-agnostic software capabilities for executing twins in production and connecting them to real-world data in real time. This platform provides the essential building blocks for digital twin developers from various specialties to get started fast, scale efficiently, and streamline changes as systems evolve over time.

Combining all the below elements of digital twins we at Altair Call it ONE TOTAL DIGITAL TWIN and in the automotive product development process it offers significant advantages in terms of time to market, cost-effectiveness, quality improvement, and delivering enhanced customer experiences.

Digital twins enable engineers to create virtual prototypes of vehicles or components, allowing for rapid iterations and testing by simulating various scenarios and assessing different design options performance before physical prototypes are built, reducing development time and costs.

By connecting the digital twin to real-time data from sensors embedded in vehicles, manufacturers can monitor overall vehicle attributes. This data can be used to analyze and optimize the design, identify potential issues, and make informed decisions for improvements.

By integrating real-time data from the production line, manufacturers can monitor quality, detect defects, and make adjustments in real time, improving overall product quality.

.Digital twins can predict maintenance needs and potential failures by continuously monitoring the vehicle's condition through sensor data. This enables proactive maintenance, reducing downtime and optimizing the lifecycle of the vehicle.

.Digital twins can be extended to include the entire supply chain, providing visibility and transparency across the network. This enables manufacturers to optimize inventory, track components, and streamline logistics, reducing costs and improving overall efficiency.

Digital twins can gather data from connected vehicles in the field to understand how customers use their vehicles and identify potential areas for improvement. This information can be used to develop personalized features and services, enhancing the overall customer experience.

Senior Director, Technology & Customer Support

-Jun-01-2023-03-42-30-7926-AM.png)

VP, Technical Operations and Data Analytics

-Jun-01-2023-03-43-37-7240-AM.png)

Technical Specialist