This edition of our contest is a wrap. Stay tuned for the Data Science Contest later this year.

Get Started with DataRobotics Optimization Winners - 3rd Quarter (Apr - Jun 2025)

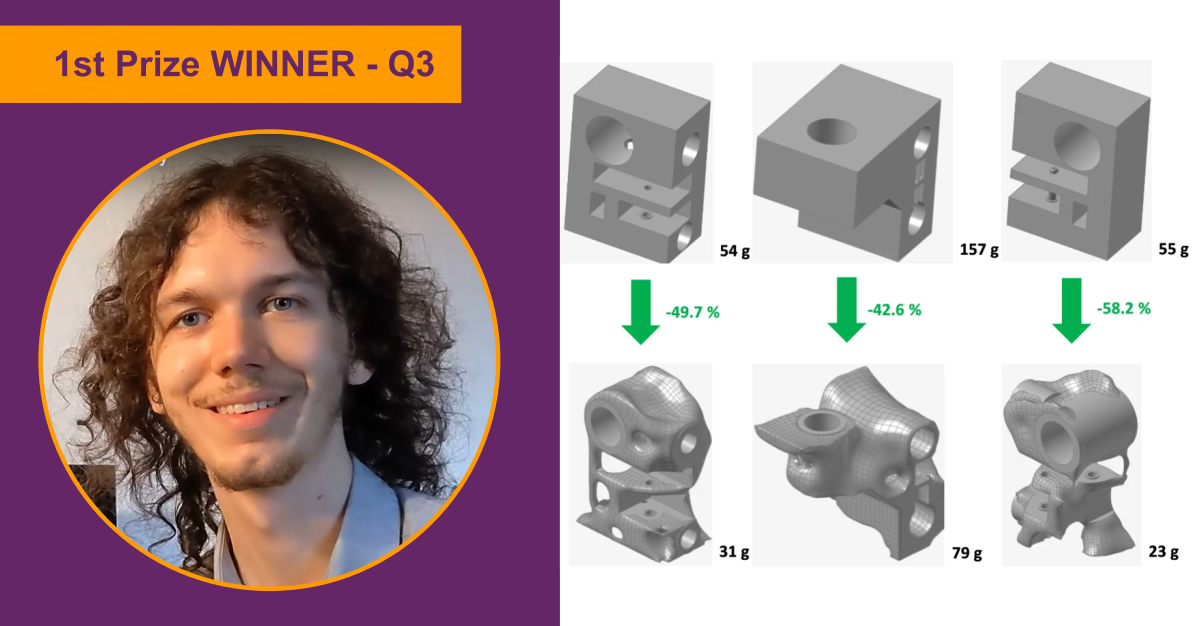

Jannis Hoffmann

University of Applied Sciences Bremen, Germany

Jannis Hoffmann from the University of Applied Sciences Bremen in Germany got us to rethink: What exactly is a robot? According to Britannica, it’s “any automatically operated machine that replaces human effort,” and Jannis’ optimized 3D printer fits the bill. Driven by his passion for 3D printing, he used Altair Inspire and its Python interface to develop a motion model that optimized three moving parts, reducing their combined mass by 50.2% for improved speed and efficiency. He also removed 47.3% of the frame’s material, making the printer lighter and more portable. Impressive work, Jannis!

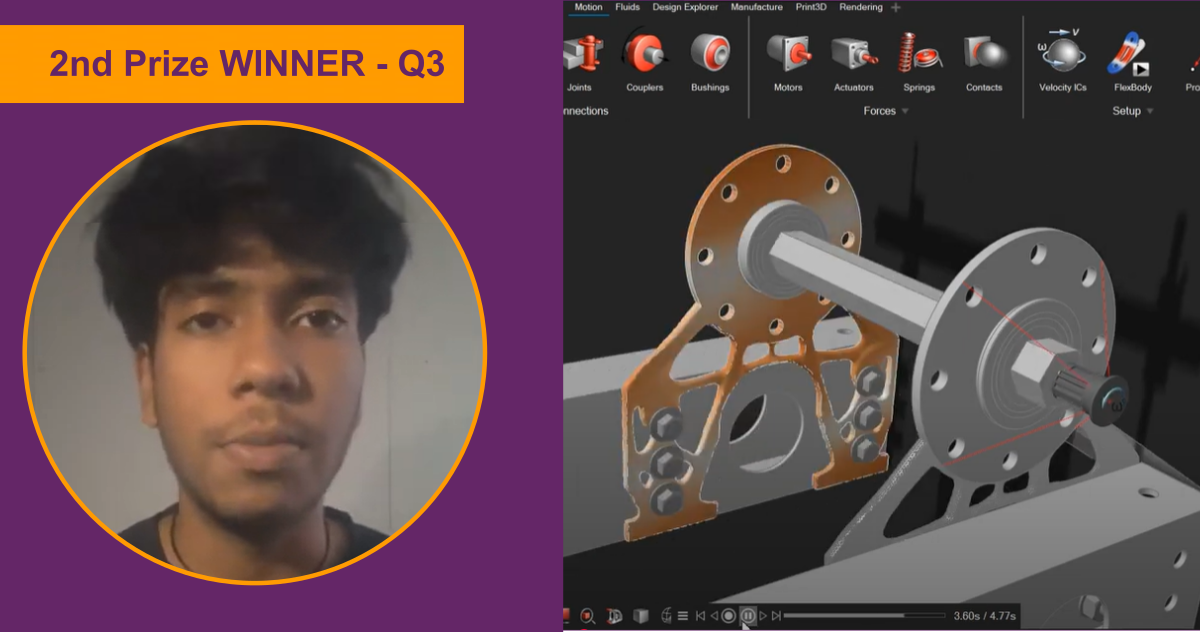

Aadi Sinha

Indian Institute of Technology in Hyderabad, India

Aadi Sinha discovered a FIRST robot designed by the Alpha Bots (Team 8608) from Battle Creek, Michigan. While their design was impressive, Aadi saw room for improvement using Altair Inspire. By combining motion analysis with topological optimization, he optimized four parts, reducing their average mass by 45%. His work made the robot lighter and more competitive. Kudos to the Alpha Bots for a great design—and to Aadi for showing how Inspire can take it even further!

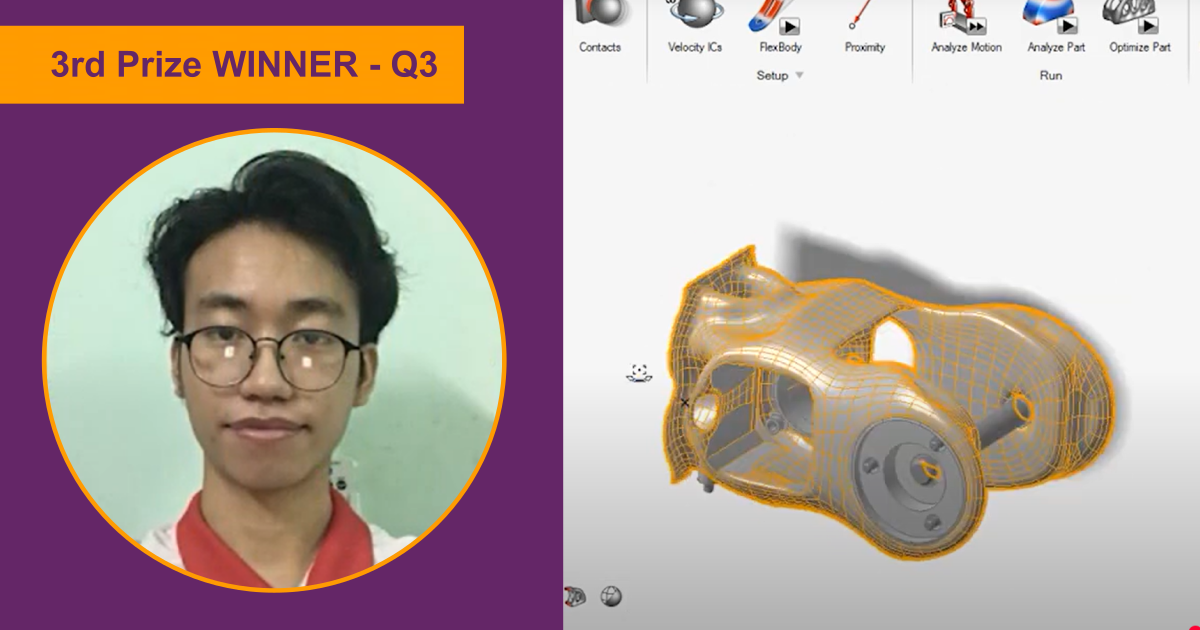

Trinh Chan Hung

Ho Chi Minh University of Technology and Education, Vietnam

Trin Chan Hung and his teammates, Nguyen Trong Hieu, Dinh Huynh Thien Dinh, and Truong Quoc Khai, from Ho Chi Minh University of Technology and Education in Vietnam, set out to improve a robot grabber using Altair Inspire. They built a detailed motion model simulating the grabber lifting a weight, rotating, and dropping it—putting Inspire’s motion tools to the test. With this simulation data feeding directly into a topology optimization, they achieved an impressive 41% mass reduction in the robot’s forearm. Well done, team—you really demonstrated how motion-driven design can lead to smarter, lighter robots!

Want To Be The Next Winner?

Learn An Altair ToolRobotics Optimization Winners - 2nd Quarter (Jan - Mar 2025)

Bright Osayande

University of Benin, Nigeria

Bright Osayande of the University of Benin in Nigeria chose a robotic “dog” to be the subject of his robotic optimization. He brilliantly utilized the power of Motion Simulation in Altair Inspire to drive the lightweighting of 3 parts of the robot's “leg”. Using forces automatically generated in the motion simulation, he reduced the weight of an already lightweight robot by an incredible 68%. Way to go Bright, you have an amazing engineering career ahead of you!!!

Colin Dagg

HOT FIRST Robotics Team #67 – Huron Valley Schools, USA

Colin Dagg, from the Huron Valley Schools FIRST Robotics HOT Team in Michigan, naturally chose to optimize his team's competition robot for this contest. Colin used Altair Inspire and the motion simulation in Inspire to improve over a dozen critical parts on their robot. The best part was that this was not just a contest entry task; this was a practical use of simulation-driven design to improve the robot that the HOT team competed with in the 2025 FIRST season. So, does Altair Inspire help build better robots? Well, if you ask the HOT Team, who by the way were the 1st place team in the Michigan District, I am guessing they would give a resounding yes. Way to go, Colin and the whole of Team HOT on their championship with an amazing job at the World Championship!

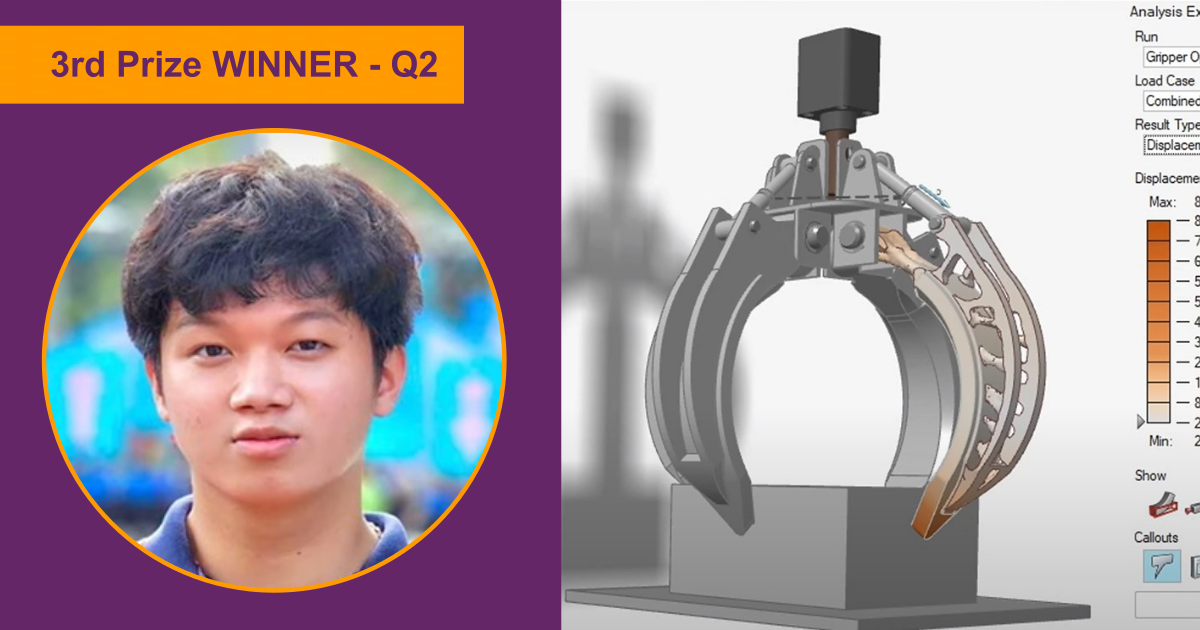

Tran Thai Dat

Trường Đại Học Công Nghệ Thành Phố University, Vietnam

Tran Thai Dat from HUTECH University in Vietnam wanted to improve the grabber on his robot design. Tran used Inspire Motion to drive his optimization and knew that lighter fingers on the gripper made for better motion and the ability to lift more weight. Tran was also keenly aware that the fingers had to remain strong and stiff so that no gripping function was lost. For Tran, Inspire provided the answer to both issues. Tran's motion-driven simulation led to a stunning reduction of 56% of the mass of the gripper. Tran immediately employed Inspire's post optimization analysis capabilities to verify that his cool new design still met his engineering requirements, and it did. Awesome job, Tran. Your new robot gripper looks amazing, and it is up to the task, confidently lifting more than ever.

Follow us on LinkedIn to stay up to date on our winners and next contest

Go to LinkedInRobotics Optimization Winners - 1st Quarter (Oct - Dec 2024)

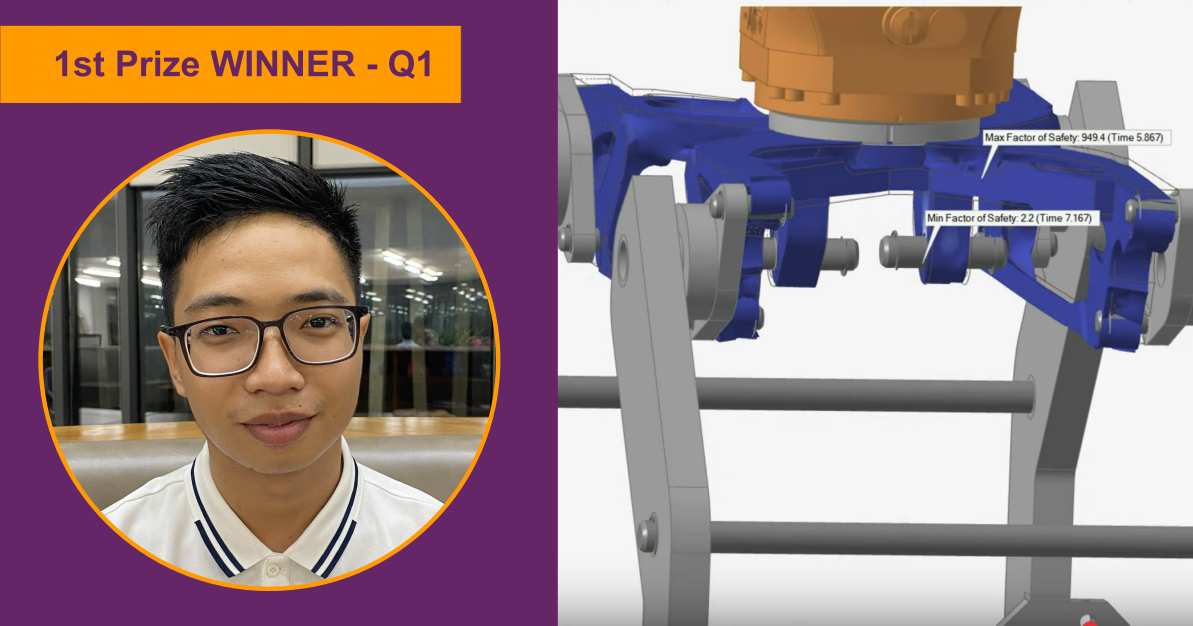

Nghia Nguyen Huu

Vietnamese-German University, Vietnam

Nghia Nguyen Huu Of the Vietnamese-German University decided to tackle an industrial robot for his optimization. He realized that the performance and accuracy of a robot can depend heavily on the tools it uses to pick and place parts. The heavier those tools are, the slower and less accurate a robot can be. He used Inspire's optimization technology to reduce the grabber weight by an amazing 55% to improve his robot design. He even took it a step further and rendered his robot motion into near photo-realistic video. Way to go, we are proud to give you 1st prize this quarter!

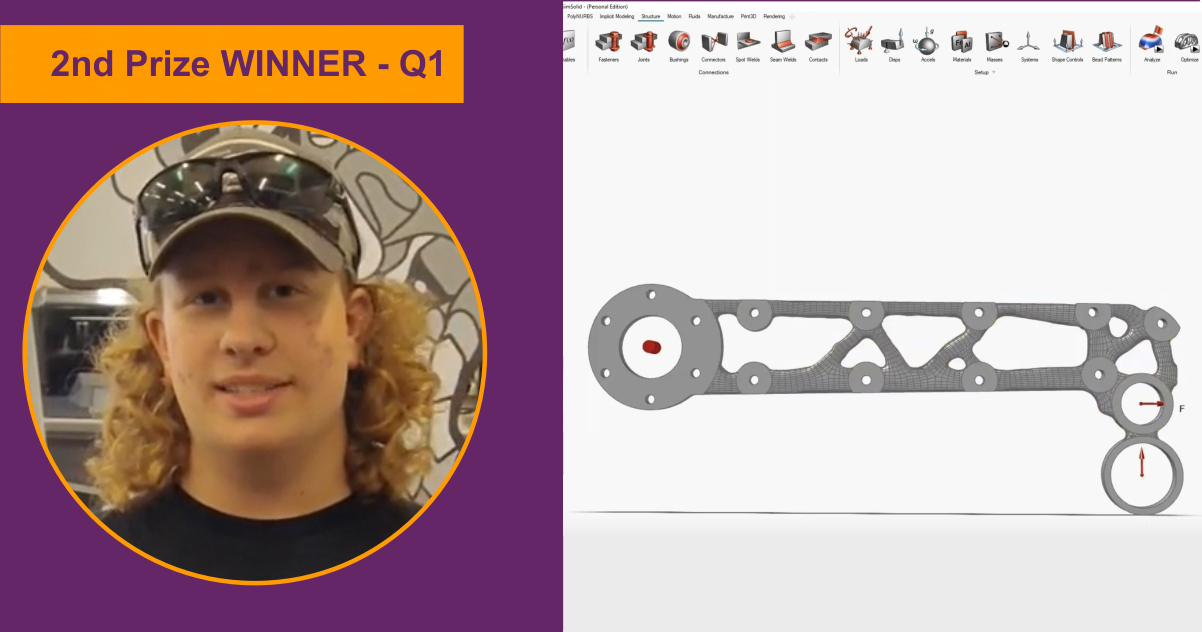

Joseph Barry - USA

Goon Squad FIRST Robotics Team 3604, USA

Joseph Barry of the Goon Squad FIRST Robotics Team 3604 is always looking to give his team’s robot an edge on the competition field. His work in Inspire and Inspire Motion was able to reduce the weight of a bracket on the intake system by an incredible 45%. Now this intake system is critical to robot performance. No intake means no scoring, so his work had to be perfect. He used Inspire to guarantee his part met their strict performance requirements and could help their robot win. Great work and we can’t wait to see the Goons in ReefScape 2025!

Madu Chukwuemeka - Nigeria

University of Benin, Nigeria

Madu Chukwuemeka from the University of Benin in Nigeria also took a stab at an industrial-style robot. Still, his approach was to tackle the main arms of the assembly. These arms are critical to the stability and functionality of the robot, but if heavy, they can also hinder and slow the movement. His work with Inspire and Inspire Motion was able to reduce 45% of his robot design, making for a faster, more agile movement. Congrats Madu, very impressive work on a complex design.