Altair Proudly Supports Student Teams

Terms of Use | Privacy Notice | Data Privacy Framework | Cookie Notice | DMCA | Whistleblowing |

© Altair Engineering Inc. All Rights Reserved.

Altair® Inspire™’s powerful and user-friendly tools help you enhance your vehicle’s performance with advanced structural simulation, lightweight optimization, and kinematic system analysis—trusted by top teams to achieve winning results.

Altair® MotionView®/MotionSolve® software simplifies and allows for advanced simulation of vehicle dynamics, deeper analysis of kinematics & compliance, and 3D calculation of internal loads between moving parts under real operating conditions.

Altair® FlightStream® software streamlines aerodynamics analysis with an easy-to-use interface and advanced solver, helping vehicle designers quickly reduce drag and improve performance.

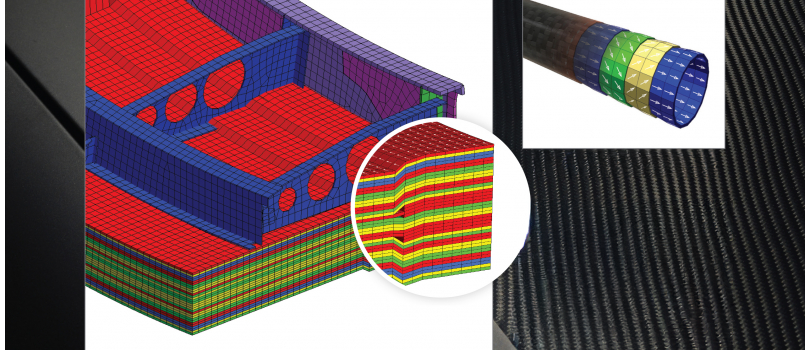

Altair® HyperMesh® and OptiStruct® enable teams to efficiently design and optimize composite vehicle structures by providing advanced stress analysis and automated development of tailored composite layups.

At Altair, we complement the work that we do with our customers in industry by making our tools available to stakeholders in academia with the ultimate goal of helping students to be real-world-ready.

Hear how your peers in solar teams found value in working with our software.

Play VideoIn conjunction with its industry-leading solvers, Inspire's intuitive interface can get you results in a fraction of the time of other leading analysis tools. From checking to determine how much a part deforms, to making sure a critical bracket can take the necessary loads without breaking, to even checking vibrational frequencies, Inspire is the ideal structural analysis tool to help you design your vehicle to go the distance.

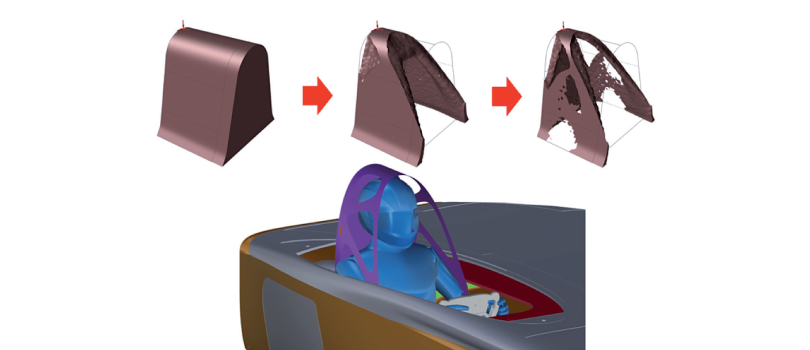

Inspire leverages the powerful optimization capabilities of OptiStruct, the pioneer tool of Topological Optimization in engineering. In a competition where weight is critical, Inspire ensures your vehicle is lightweight without compromising strength or safety. It supports various manufacturing methods like milling, casting, cutting, and 3D printing. Design a faster, more efficient vehicle with Inspire.

A complex vehicle has numerous intricate moving parts. Ensure they operate correctly using Inspire's motion simulation tools, which include automatic joint creation, simple motor and actuator setup, and rapid contact generation. After your analysis, you can easily extract joint and contact forces and integrate them into structural analysis and optimizations for dynamic loading.

These posts will help you learn the basics of suspension modeling and design using the power of template-driven, parametric MotionView templates. While we are currently working on implementing a SolarCar library, utilization of the FSAE library, which is also a track event, will accurately simulate your suspension designs and vehicle dynamics.

FlightStream is equipped with unique point-and-click capabilities for problem setup and pre- and post-processing tools that allow real-time case visualization. This YouTube playlist will provide you with an easy, guided path to learning FlightStream in preparation for utilizing the software to rapidly create aerodynamic studies of your vehicle.

These resources will give you a head start to get you on your way to building better, lighter, stronger vehicles with the power of composites. You can learn the intuitive pre-processing in HyperMesh that mimics the manner in which composites are laid up on the shop floor and build your skills to optimize and automatically generate ply shapes and stacking order for the ideal layup.

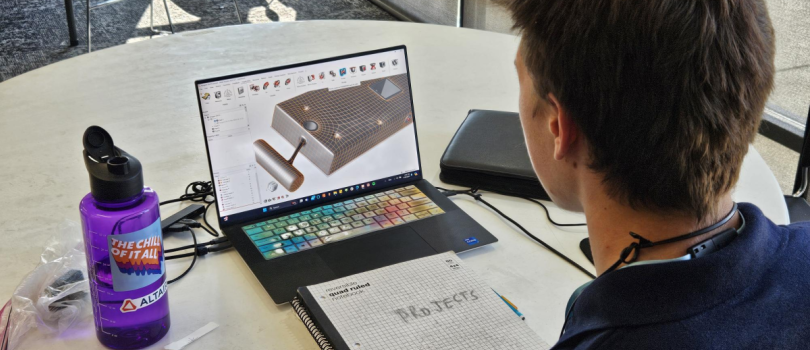

Learn how Altair Inspire helps student teams use simulation-driven design to accelerate innovation, optimize structures, and improve performance. This workshop demonstrates how integrating simulation early reduces development time, lowers material costs, and provides valuable engineering insights for projects like race cars, robots, and complex assemblies.

Altair MotionSolve enables Formula SAE teams to meet tight deadlines and resource constraints by providing advanced simulation tools and a comprehensive vehicle model library, helping students quickly analyze designs, address engineering challenges, and enhance vehicle performance.

Library files and more information about this topic can be found here.

This session demonstrates how PSIM and HyperStudy create automated efficiency maps for PMSM motor drives, streamlining parameter analysis and reducing simulation time. The workflow is fast, requires no programming, and simplifies setup while allowing flexible customization.

Simulation files for all examples shown in the session can be found here.

Aerodynamic design is vital in student competitions supported by Altair. Traditional CFD tools slow down the process due to complex setups and long run times. Altair Flightstream is a modern panel method solver that simplifies model building, is easy to use, and delivers high accuracy much faster than standard methods. This presentation shows how Flightstream can be applied throughout the aerodynamic design process, from early concepts to detailed development.

"Altair solutions played a significant part in this extraordinary result by helping us to design the optimal carbon structure. They will also help us in the future to design and further optimize our BluePoint solar car for upcoming competitions. It really is an unbelievable feeling to consider ourselves as world champions of this race, "

To simply participate in this competition, you don’t need tools like Altair’s leading-edge modeling and simulation technology — but to win, you do!

“We’ve achieved significant weight reduction and rigidity strength by optimizing the material characteristics from our design.”

"This is truly thanks to the efforts of everyone who has been involved with our team, including sponsors. Without your support, we simply could not be building and racing solar cars. We were able to make Freya the car she is now because of your help!"

Learn from Altair Experts on Vehicle Design and become fully equipped to design the most lightweight, aerodynamic, and energy-efficient vehicle possible.

Create lightweight designs and use Altair® Inspire™ to simulate how your structures can be as light as possible. In addition, you can simulate manufacturing processes like 3D printing with Inspire.

Learn how to improve your vehicle's performance with multi-body simulation using MotionView/ MotionSolve software from Altair.

This session covers beginner to advanced workflow and feature-set demonstrations, such as:

- Half and Full Vehicle Assembly using the Assembly Wizard

- Driven and Non-Driven Standard Events

- Event-Specific Automatic Post Processing

- Simplified Design Data and Architectural-Level Studies

- Kinematics and Compliance Optimization

- Rigid and Deformable Tire/Road Modelling Options

- Integrating Nodal and Modal Flexible Bodies

- RealTime Simulation

- Customization Through Scripting and User Assembly Libraries

- Process Automation Using Altair Compose

Altair® FluxMotor® will help you to generate and evaluate concepts of your electric drives. Use the simulation to evaluate and optimize the performance of your engine.

In this session, you will learn about Data Analytics and Data Science, and how to make predictions using Machine Learning about downtimes of systems.

Altair Concept Simulation for a Baja Team by Thomas Neumaier

The Case Western Reserve University Baja Team uses Altair Inspire to analyze and optimize parts on their vehicle, which speeds up the design process, allowing for all new parts to be fabricated every year. Additionally, with the use of Inspire, the team was able to completely redesign their gearbox, resulting in a 5% weight savings, a 40% reduction in machining time, and a part that never failed.

Evaluate Forces in Motorcycle Suspension by Jan Grasmannsdorf

Learn how to use Altair Inspire to determine the kinematic forces of a motorcycle suspension arm. The assembly loads will be used to optimize the suspension rocker. Finally, we will showcase how to simulate the 3D printing process of the optimized part.

Design of a Rocker Arm by Jan Grasmannsdorf

Printing Simulation of a Rocker Arm by Jan Grasmannsdorf

Power electronics is an essential part of electrification and e-mobility. For over 25 years, PSIM has been enabling innovation as a leading tool for power electronics and motor drives. With the rise of wide band gap devices and multi-level and multi-modular converters, PSIM is again helping pave the way at the forefront of the industry. This webinar will introduce how PSIM can design and simulate power electronics and motor drive systems, and help you reduce costs and time-to-market while improving the reliability of your electrification projects.

This webinar focuses on the design of electric motors and will show how multiphysics simulation and optimization allow innovation and reduce costs while considering multiple design constraints. Spin Applicazioni Magnetiche, a company creating innovative solutions of rare earth-free synchronous reluctance motors for various power levels and applications will present a practical use case, including a detailed comparison between simulation and test results, considering electromagnetic, thermal, and vibration responses.

The Brunel Solar Car team used Altair FlightStream to run thousands of aerodynamic simulations, accelerating development and enhancing vehicle performance. This approach enabled rapid design refinement and contributed to winning first place at the 2025 Bridgestone World Solar Challenge. The presentation will showcase these achievements with a live demo of FlightStream using the team's solar car model.

NJIT Highlander Racing uses Altair HyperWorks to quickly develop and refine their double wishbone suspension for Baja SAE, addressing challenges like long suspension travel and high impacts. The software enables detailed analysis of wheel alignment and movement, reduces reliance on physical tests, and supports evaluation of different damping and bushing options, helping the team make confident, data-driven decisions to boost performance in competition.

Penn State’s Nittany Motorsports used Altair SimSolid to streamline the design of their electric formula racecar chassis, achieving a 9.3% weight reduction without sacrificing strength or safety. This led to higher competition scores and supports their ongoing shift to advanced, simulation-driven design for future improvements.

This session covers essential techniques in composite design, focusing on practical ways to improve efficiency and avoid common mistakes. Key topics include drape analysis, composites optimization, and the benefits of different modeling approaches. Altair experts and the Oxford Brookes student team discuss how these methods helped reduce the weight of their 2025 car by 24%, resulting in significant performance improvements.

The Veloce Racing India FSAE team used Altair’s advanced simulation tools to improve vehicle safety, performance, and reliability. By validating designs and optimizing key components, we reduced weight without compromising strength, resulting in multiple award wins. This presentation demonstrates how Altair’s software and streamlined workflows enabled innovation throughout our design process.

Altair Inspire enabled the UBC Solar team to quickly learn and optimize key mechanical components, leading to a win at the FSGP 2025 Altair Challenge. By using intuitive tools like OptiStrut and SimSolid, they reduced vehicle mass and improved performance.

The presentation introduces the Lunabotics competition and MTU's team, the Astro-Huskies, and shows the evolution of the mobility system using Altair Inspire for optimization and analysis. Inspire was key to transitioning from a skid-steer system to a four-wheel steer system. It enabled the team to meet mass requirements while transitioning to the more capable four-wheel steer system by aiding in the design of strong, stiff, and lightweight components.

The NSSUR Formula Student Korea team used Altair HyperWorks, SimLab, and CFD to enhance vehicle components and optimize composite designs. This led to significant weight reduction and improved structural strength in their competition car. In the Altair Optimization Contest, they reduced the EV battery lower cover’s weight by 34.8% and increased torsional stiffness by 30.2%, highlighting the effectiveness of Altair solutions from design through validation.

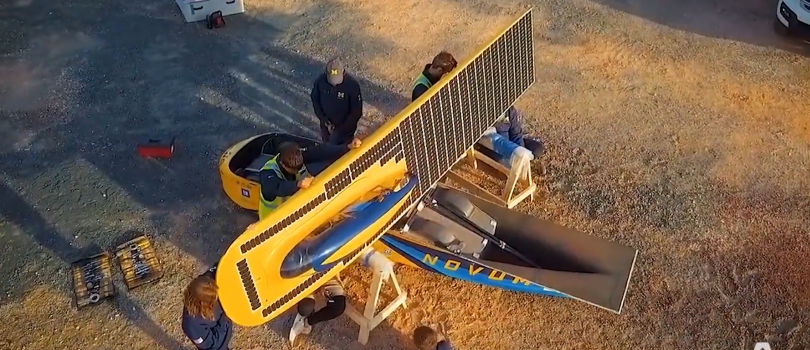

Watch how the University of Michigan Solar Team uses Altair's cutting-edge tools to create lightweight, safe solar vehicles through material optimization and composite analysis.

Using Altair simulation software, Gurit supports Western Sydney University's Bridgestone World Solar Challenge team, helping them design the most efficient and aerodynamic car possible, while ensuring driver safety and adhering to class rules.

See how Altair's Software is used to get the University of Michigan's solar car, Novum, to the next level to compete in the World Solar Challenge in Australia and the American Solar Challenge - crossing an entire continent in both cases just on the power of the sun alone.

The Kogakuin solar team, comprised of more than 300 students, are focused on performance, growth, self-reliance and teamwork through science and engineering activities. Established in 2009, the team has won three consecutive national championships.

Altair is devoted to playing a pivotal role in nurturing the next generation of engineers and innovators by actively supporting student engineering teams. We empower students to develop problem-solving skills and gain real-world engineering experience by supplying free software access and support for teams.

During the annual Formula Sun Grand Prix event organized by the Innovators Educational Foundation, Altair hosts a challenge that allows participating solar car teams to test their engineering skills and enhance their analysis and optimization abilities.

In 2025, teams were tasked with redesigning a roll cage using only the Altair tools provided. In addition to the opportunity to win a $10,000 cash prize or other exciting rewards, participants had the chance to improve their skills in optimizing components of their solar car, giving their teams a competitive edge in the overall contest.

🏆 UBC Solar won the big check this year with the best design out of the 18 participating teams.

Earning certification in Altair software products demonstrates advanced skills in cutting-edge tools used across industries for simulation, AI, and data-driven design. This credential highlights your expertise to potential employers, setting you apart in a competitive job market and equipping you with practical knowledge that aligns with real-world applications, making you a more desirable and job-ready candidate.