Data to Value Symposium

Altair is driving the future of technology convergence with open-architecture solutions for Data Analytics and AI, Simulation and High-Performance-Computing.

Explore enabling technologies driving digital transformation at our media lunch and digital twin coffee on April 18th, 2023 at 1:00 - 2:00 pm on booth E40 in hall 17 during the Hannover Messe.

You can't make it? Request an Altair customer or expert interview on the right.

April 19, 2023 at 9 am - 1.30 pm

Hannover Messe Convention Center Room 3B

AI for the Factory Floor

75% of all AI Models don't go into Production - Why?

At this symposium, we will discuss with customers and experts how to establish self-service Machine Learning in every organization, the importance of enabling domain experts for AI, and why the cloud is a good place to start.

Why is not every factory ran by an AI?

The reality is different than the hype. While most companies want to invest into data analytics we still need to remark, that only 13% excel at delivering on their data strategy. A recent study by Forrester also found that only 13% of models get industrialized. This means that only one out of 8 companies succeed.

Download the blueprint to see what is needed for AI on the factory floor.

Join us at booth E40 in hall 17.

“…we reduce energy loss, balance peak loads, and develop more efficient operating strategies. …”

“With Altair digital twin technology, we improve our machine efficiency and realize significant energy savings – thereby making each cup of coffee more sustainable!

We achieve these savings through early, extensive virtual prototype testing, which empowers us to optimize our products better and faster than ever before!”

Maurizio Tursini

CTO, Gruppo Cimbali

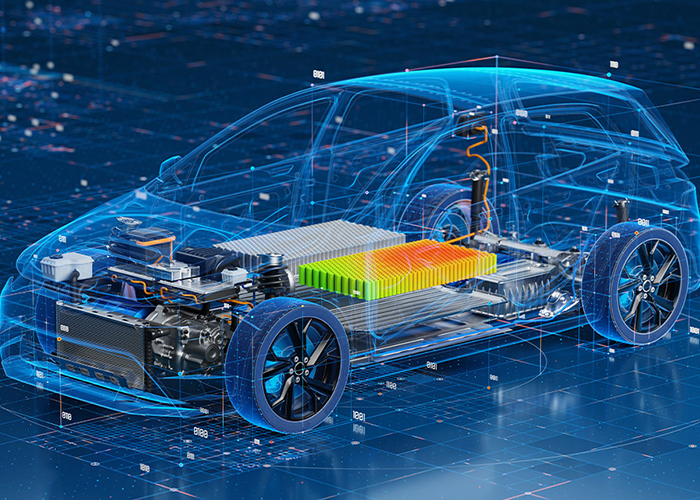

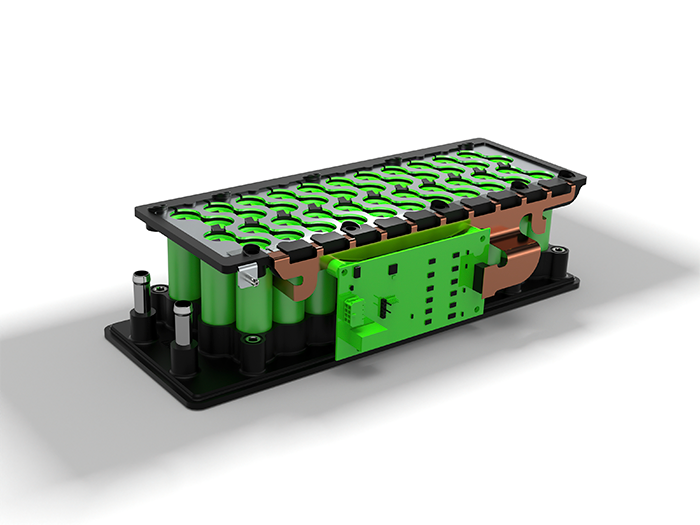

“… we are disrupting battery development processes with an intelligent Digital Twin…”

8 cooling cycles saved,

60% cooling time reduction

= 5 Miles range increase

“… The Danecca Team built the physical & virtual Twins in under one month. Now we accurately test development and showcase new battery/BMS innovations within a linked environment.

A Digital way forward for the Accleration of E-NNOVATION!”

Danson Joseph

Managing Director, Danecca

Watch the Recording of the Danecca presentations:

Creating an Intelligent Digital Twin to Optimize Battery Performance

Disrupting the Battery Development Process with an Intelligent Digital Twin

“Hardware updates reduce resources and power consumption.

… Optimizing for performance and manufacturability allows to achieve sustainability goals within economic boundaries!”

Dennis Middelmann

Co- Founder amprove

amprove TGU – TTI GmbH

“… Lighter than other motorcycles with a comparable engine power!

Faster than other motorcycles with similar weight… “

400 Nm peak torque

103 kg weight

“… Hardware testing is not feasible for a startup...

Simulation makes visions come true!....”

René Renger

Founder & CEO NOVUS GmbH

-Feb-09-2023-02-04-38-5130-PM.png?width=1008&name=MicrosoftTeams-image%20(7)-Feb-09-2023-02-04-38-5130-PM.png)

Digital Twin understands and reacts to varying material properties and

“… A comprehensive Digital Twin is inevitable to understand the impact of multiple parameters on the forming process and based on this improve the quality of the final product. … !”

Antonio Del Prete

– Associate Professor of Manufacturing Technologies and CEO at

Advanced Engineering Solutions srl