Discover Simulation-driven Design for Manufacturing

When developing a new product, manufacturers want to be sure their development process is going to be as efficient as possible. With a SDfM approach, product designers can be confident in their chosen manufacturing method because design flaws can be detected much earlier and corrected before any physical prototyping has to be done. Implementing simulation early allows engineers to create innovative, manufacturable products beginning at the earliest stage of production. Altair Inspire™ products cover all facets of manufacturing, from casting and PU foaming, to extrusion and metal forming, allowing for quick, generative design for all manufacturing processes.

Please join Altair for an exclusive webinar covering the industry's most powerful and easy-to-use virtual Manufacturing suits.

During this event, you will learn, how to plan for the manufacturing process & understanding critical parameters, Defects and issues, and challenges. Also, ideas of enhancing your manufacturing process, targeting, improved Yield, optimal energy, lowering wastage, improve tool life and enhance production quality.

Interested users from India, participating in this Webinar, will get access* to a Free Trial and Online training to these easy-to-use design and simulation solutions.

Who should attend?

This webinar is a must for all design engineers, mechanical engineers, Tool and die design engineers, Material Engineers, and Manufacturing process engineers.

2:00 PM- 4:00 PM Meet the Experts -Case Studies on using Altair Mfg Simulation & Q&A

2:00 PM- 4:00 PM Meet the Experts -Tips and Tricks using Altair Mfg Simulation & Q&A

Download Outlook Calendar

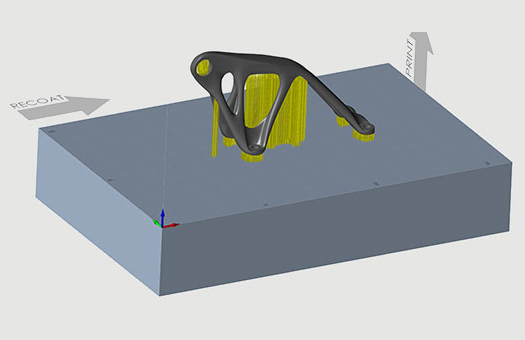

3D Printing

Altair Inspire Print3D enables teams to cut product development and additive manufacturing costs by reducing material usage, print times, and post-processing. It provides a fast and accurate toolset for the design and process simulation of selective laser melting (SLM) parts. The easy-to-use advanced thermo-mechanical simulation enables design engineers to develop parts ready for additive manufacturing. By capturing behavior independent of the printer type, designers can evaluate and easily modify critical process variables.

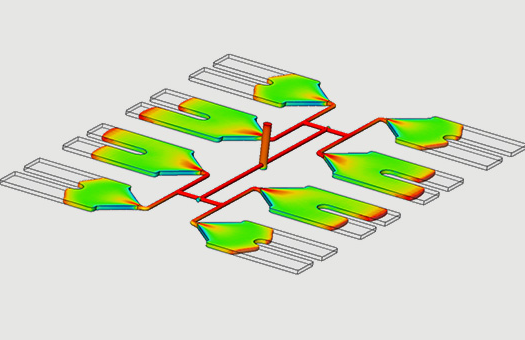

Injection Molding

Altair Inspire Mold is a modern, integrated software to streamline design for manufacturing (DfM) of injection molded components. Fast, accurate simulations answer the question “will it fill?” for even large, complex parts in under an hour. Identify potential manufacturing defects early in the development process and make better, more informed design decisions. Leap from manufacturing “know how” to “know why” and deliver superior products, reduce scrap, and slash tooling rework costs. Additionally, Altair Inspire PolyFoam simulates the polyurethane foaming process.

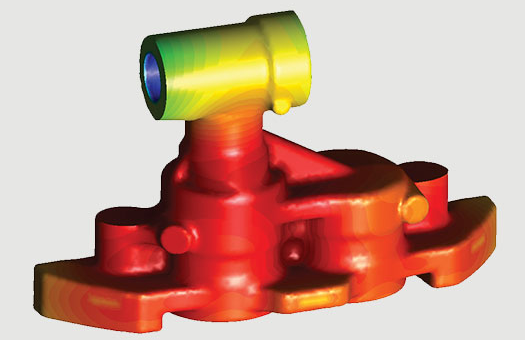

Casting

Altair’s offering includes a fast casting process simulation software that allows the user to enhance and optimize their manufactured components in order to avoid typical casting defects. Altair Inspire Cast is a simulation environment focused on creating high-quality components with increased profitability through a highly intuitive user experience catering to beginners and experts alike. Additional casting simulations products are accessible through the Altair Partner Alliance.

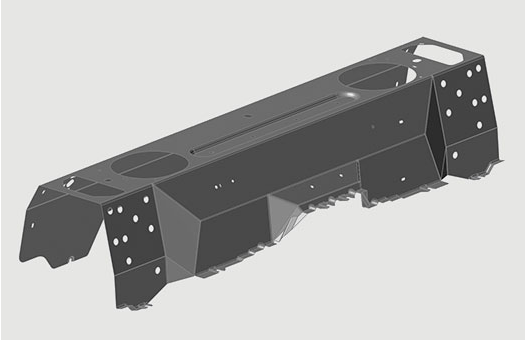

Metal Forming

Altair Inspire Form is a sheet metal forming simulation software that enables users to optimize their products for manufacturing, with the consideration of early formability, material utilization and cost. Cold and hot sheet metal forming, tube bending, hydroforming, and composite forming are supported. Run early manufacturing feasibility analysis within seconds or perform advanced process validation, optimization, and virtual try-outs leveraging an accurate, highly-scalable solution.

Extrusion

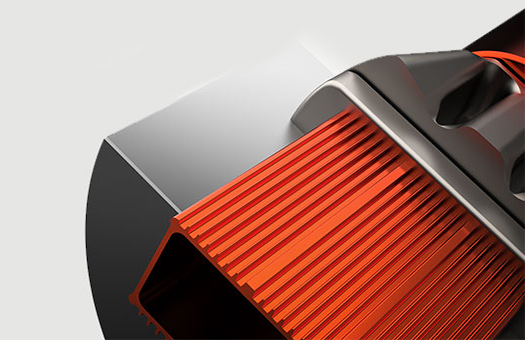

Every extrusion company is looking to eliminate costly prototypes and reduce redesign cycles. With Altair, advanced physics simulations are now accessible to organizations of all sizes. Altair Inspire Extrude is a simulation solution for both metal and polymer extrusion. It helps achieve productivity gains by reducing product development costs and improve extrusion quality, increasing production yield. Lower scrap rates can be achieved by exploring process improvements on a virtual press.