Simulating Pharmaceutical Manufacturing Processes with EDEM

Live Webinar – Tue, April 06 | 11 a.m IST

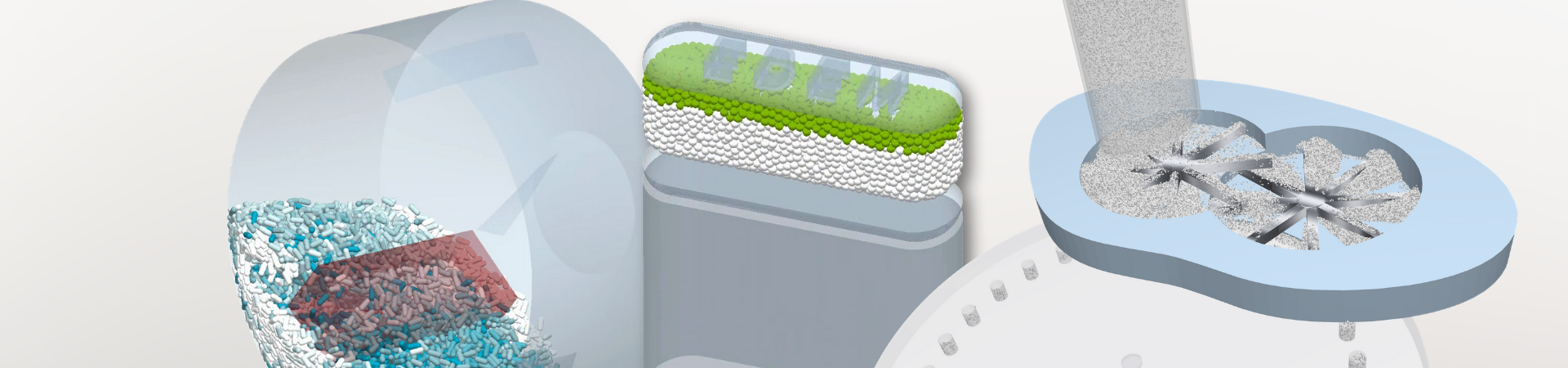

This webinar emphases on pharmaceutical mfg. the process which mainly deals with powders and their interactions with equipment. Powders are a fundamental material used widely in the process industries including pharmaceutical, food, chemicals, cosmetics, and additive manufacturing. Powders are involved in a range of applications from storage, transportation, and delivery to processing stages such as mixing, compaction, or agglomeration. When simulating powder handling processes, EDEM can help identify the root of the problem and serve as a virtual prototyping tool to test potential solutions and improve understanding of processes. In addition, the fundamental insight that EDEM provides into the micro-mechanics of granular systems can be used to meet otherwise difficult challenges, such as process scale-up and the transition to continuous manufacturing. This has made EDEM an indispensable tool for optimizing process design and operation in the powder processing industries.

This 45mins webinar will cover:

- Context and Challenges

- Introducing EDEM simulation technology & benefits

- Material modeling and calibration

- Common applications: powder mixing, granulation, milling, die filling, tablet compaction, and tablet coating.

Who should attend?

- Engineers, scientists, and researchers involved in the drug product manufacturing process.

- Anyone interested to learn more about the applications of the Discrete Element Method in the pharmaceutical industry, what key insight it can provide, and the benefits it can bring to optimize drug development.

Why should you attend?

Engineers, scientists, and researchers who involved in the pharmaceutical manufacturing process and willing to improve product quality can attend this webinar

- Predict the spatial and temporal evolution of tablet coating

- Examine the effect of spray pattern, spray rate, fill level, and rotational speed

- Obtain a greater understanding of powder behavior

- Increase process efficiency and capability

- Optimize process configuration

- Reduce costs and dependence on physical prototyping and testing

- Drive product and process innovation

- Improve scale-up procedures

- Improve product quality

- Get products to market quicker