Towards More Sustainable Steelmaking

Transforming Steelmaking Operations with Simulation

The steelmaking industry is facing a range of challenges with the need to improve energy efficiency and to reduce carbon emissions while maintaining steel quality.

To work towards decarbonization and the development of next-generation blast furnaces and processes, steel companies worldwide are partnering with Altair to access the latest simulation technologies and transform their steelmaking operations.

Bulk and granular materials such as iron ore, coal, pellets and sinter are at the core of the steelmaking process and efficient handling and processing of those materials is critical to achieve efficiency. Altair® EDEM™ software enables steel companies to analyze the flow and behavior of materials through each segment of their equipment and operation. This provides them with unique insight into their operations and enables them to improve the design of devices such as charging systems and to optimize key processes.

Check the resources below to find out more about EDEM simulation software and its applications and discover how ArcelorMittal, Paul Wurth and other leading steel companies use this technology to improve steel quality, energy efficiency and blast furnace performance.

Free Webinar June 6th, 9 AM CEST

Discover the Future of Steelmaking

Take your iron & steelmaking processes to the next level. Join our free webinar on June 6th at 9 AM CEST and learn how to optimize transportation, raw material handling, mineral processing, blast furnace and sintering. Discover how to reduce costs, improve efficiency, and increase output while maintaining steel quality and reducing carbon emissions. Register now and revolutionize your steelmaking operations.

Register Now

CUSTOMER STORY

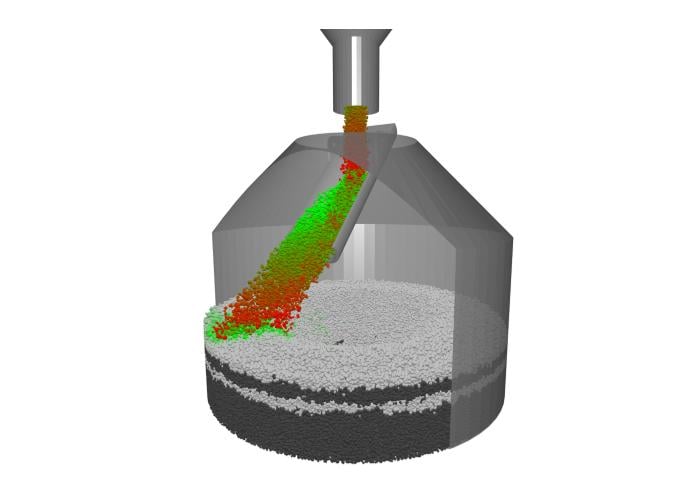

Made of Steel - ArcelorMittal Optimized Sinter Cooler Charging System

Find out how ArcelorMittal used Altair EDEM software to simulate and analyze the granular flows in the charging chute of a sinter cooler plant and it how it helped them improve the reliability and efficiency of this device.

READ CASE STUDY

Customer Presentations

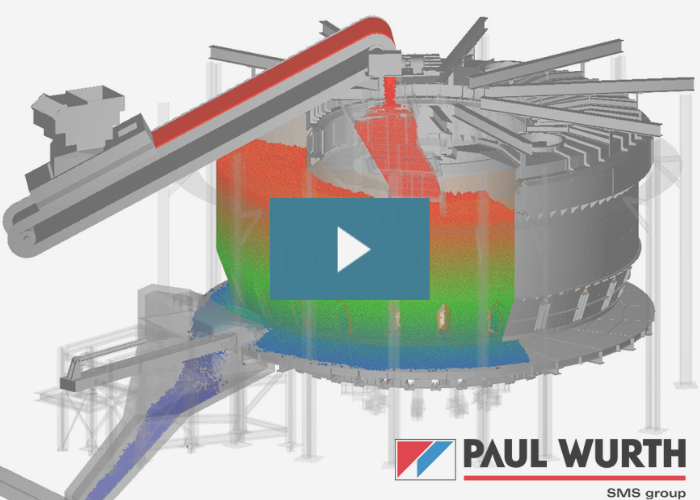

Simulation of Segregation in Blast Furnace Plant – FIFO Evaluation

Learn how Paul Wurth used Discrete Element Method (DEM) simulations coupled with a FIFO evaluation to increase their knowledge of the important factors influencing the segregation and improve the design of the complete material handling.

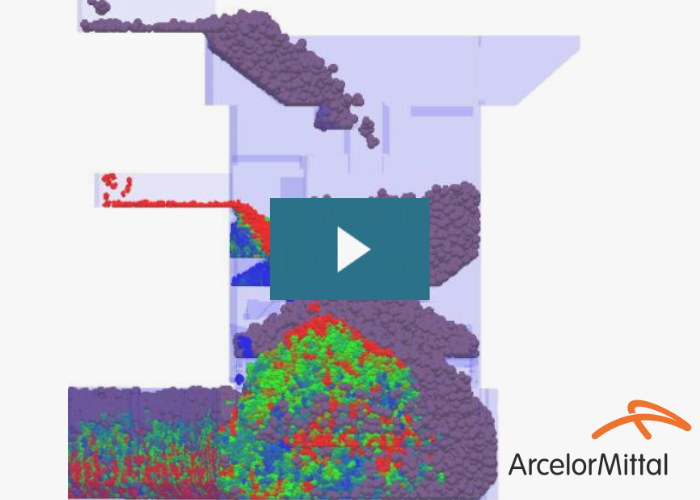

Some Usages of EDEM Software at ArcelorMittal R&D (1)

In this presentation two use cases are discussed:

• how to predict wear to help increasing equipment lifespan

• how to design a sinter-cooler charging chute to optimize segregation patterns

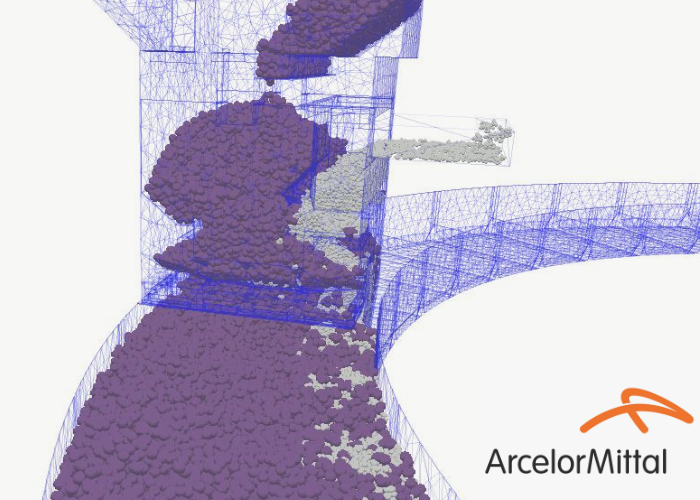

Some Usages of EDEM Software at ArcelorMittal R&D (2)

In this presentation two use cases are discussed:

• how to set up a predictive model of the sinter charging process in which segregation takes place

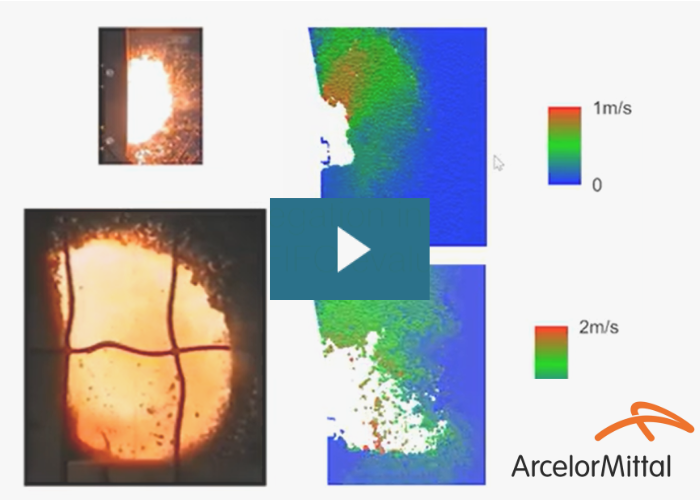

• how to simulate a pilot scale blast furnace raceway with only coke particles using EDEM and CFD