Simulation Academy

Simulation trends for all steps in the development process

Increase product quality and improve product performance

The complexity in product development is constantly growing. The increasing integration of mechanics, electronics and software in the product development process requires the use of comprehensive simulation and the interaction of simulation and test data, from the concept phase through the manufacturing process to the prediction of product behaviour.

In 5 selected, practical presentations, our experts will show you the latest trends and methods for significantly improving the quality of your products with the help of end-to-end simulation tools and AI.

The topics of our summer academy

- Altair® Inspire™ Cast - A unique experience in the development of cast parts and casting processes

- eMotor Director – A paradigm shift for the multi-physics design of e-motors

- Altair® HyperStudy® – Automated design generation and data-driven optimization

- Applications of the discret element method (DEM) in industry using Altair® EDEM™

- From math and scripting to multidisciplinary system simulation - Model-based development with Altair Compose® and Altair Activate®

Interesting for everyone in the product development process

This simulation academy has been designed to address the needs and challenges of designers, product engineers, constructors, manufacturing specialists as well as system developers.

Simulation Academy Topics:

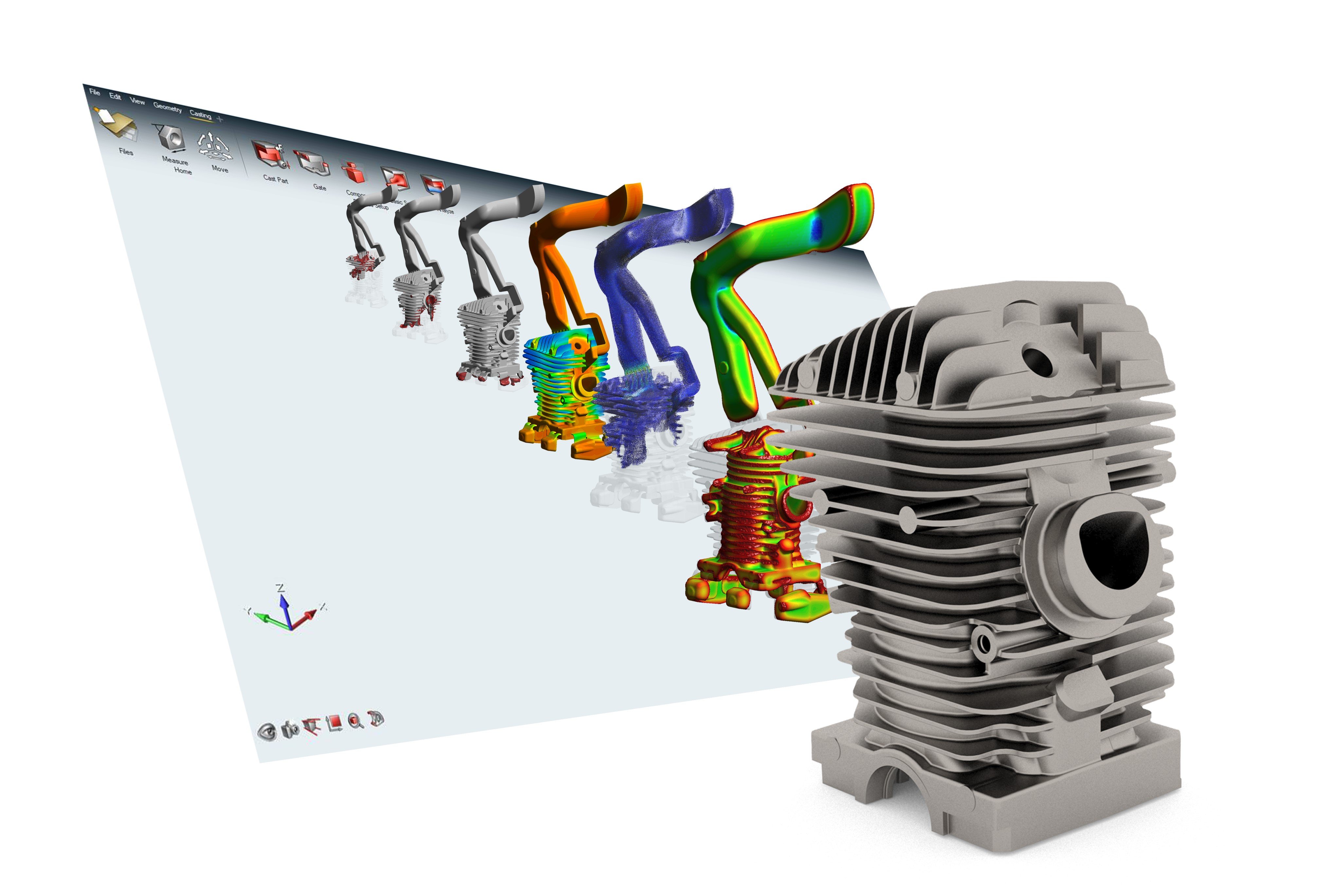

Altair® Inspire™ Cast - A unique experience in the development of cast parts and casting processes

Inspire Cast is a fast, easy and accurate casting simulation tool focused on creating high-quality components with increased profitability. It is the only tool that meet the requirements of both beginners and experts, from product designers to foundry engineers.

Early in the design phase, users can visualize and fix typical casting defects to avoid costly downstream corrections. Guided process templates take you to simulation in five easy steps. The two-phase finite element formulation allows you to capture the filling and solidification process with great precision.

In this session, you will get an overview of Inspire Cast and learn how it provides users with a unique experience for casting and process development, especially in the early design phase. New features, such as improvements in mold filling, will also be presented.

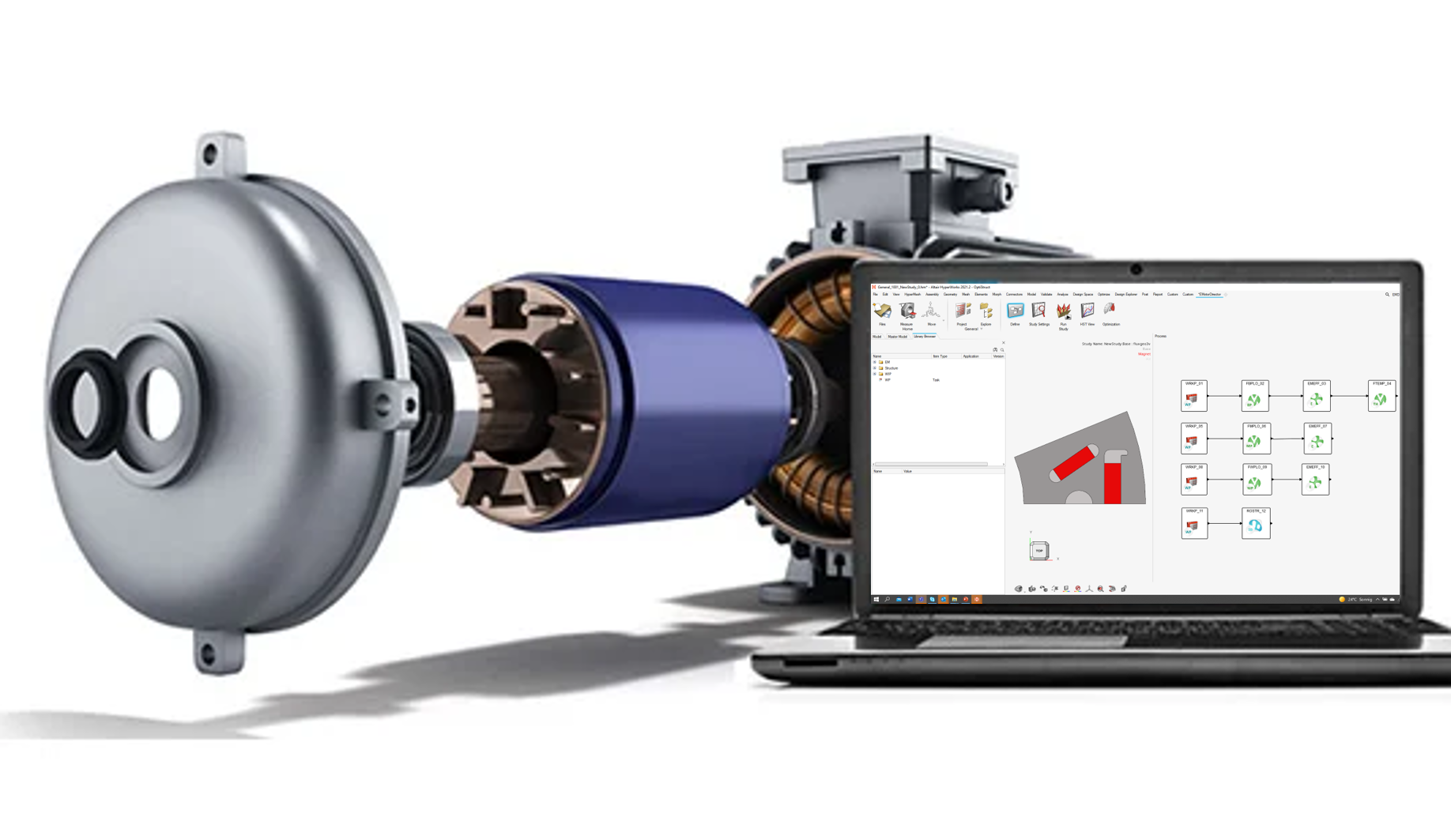

eMotor Director - A paradigm shift for the multi-physics design of e-motors

The holistic and multi-physical development of e-motors requires a new way of thinking and a new development strategy. At Altair, we meet this challenge with simulation and data-driven development. Simulation and optimization are key development tools to ensure that all technical requirements can be met at minimal cost and time.

eMotor Director is the direct implementation of this strategy: it enables development engineers to quickly and flexibly define and perform multi-physics studies. From these studies, effective optimization strategies and machine learning can then be used to perform "design explorations" to find optimal characteristics for one or more motors. In doing so, an almost infinite number of possible designs can be checked and evaluated in a very short time.

In this workshop you will discover the key features and benefits of simulation- and data-driven development and representation of e-motors in eMotor Director.

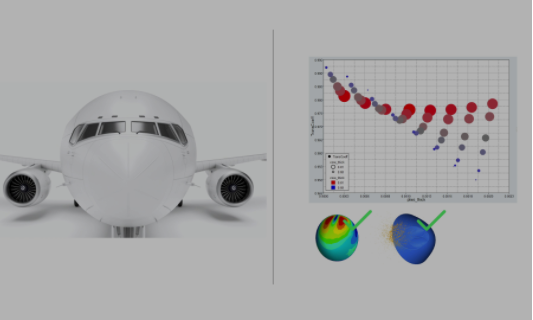

Altair® HyperStudy® - Automated design generation and data-driven optimization

Development engineers, designers and component managers face a wide variety of challenges in their daily work: Shortened development times have to be met, complexity and the number of variants continue to increase, multidisciplinary requirements for products sometimes go beyond the development process and are constantly changing. At the same time, they must be able to operate various modular systems.

HyperStudy is the ideal tool for these requirements and, as a generalist, multidisciplinary design exploration and optimization software, offers the possibility of automatically generating optimal solutions. In addition, trade-off studies can be performed, key influencing variables can be identified, and machine learning models can be trained and deployed.

In this workshop, you will get an insight into HyperStudy and learn about the key features and benefits of simulation- and data-driven optimization.

Applications of the discret element method (DEM) in industry using Altair® EDEM™

Bulk material is everywhere! It comes in all shapes and sizes: Stones, powder, tablets, granules, dirt or grain are just a few examples. It can be found in about 70% of all industrial processes and is an issue in a wide variety of industries, such as mining, pharmaceuticals, agriculture or in the automotive industry.

Bulk materials are complex in their behavior and this poses challenges for engineers, as granular materials often have a significant impact on the performance of a device or the efficiency of a process. Simulation-based design earlier in the design cycle can reduce the amount of prototype testing, cost and time, and deliver an improved design.

The Discrete Element Method (DEM) is a discrete matter simulation method that captures the dual nature of fluid and solid properties of granular material flow. In this workshop you will learn how EDEM can be used by engineers in a variety of industries for virtual testing. And, of course, how you can gain critical insights into the interaction of materials and plant during a range of operating and process conditions.

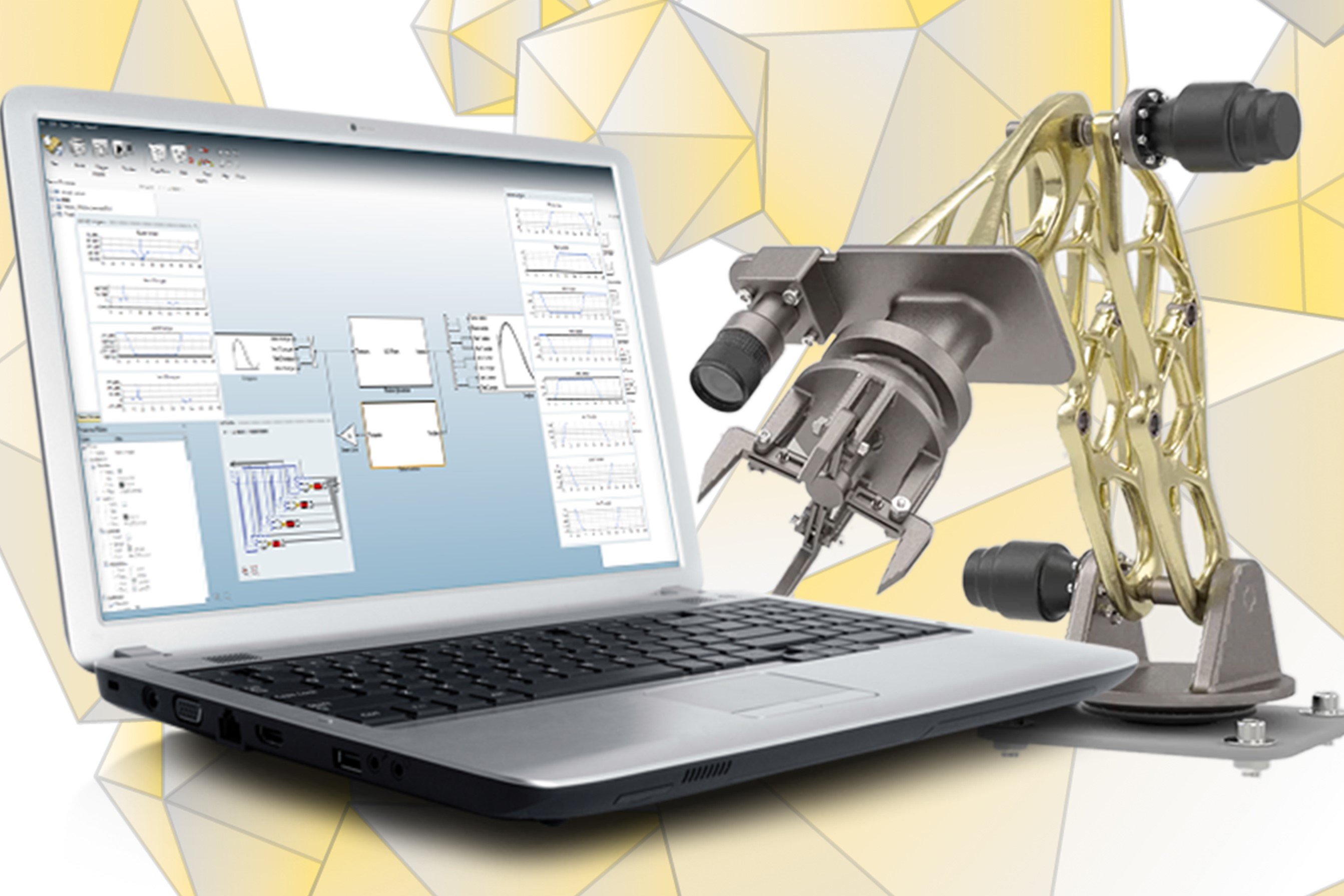

From math and scripting to multidisciplinary system simulation - Model-based development with Altair Compose® and Altair Activate®

The steadily increasing complexity of products in conflict with shorter development cycles makes it essential to shift development efforts to earlier and earlier phases. In the course of this so-called frontloading, model-based approaches for the evaluation and optimization of mechatronic systems in particular are becoming increasingly important.

One tool for performing calculations and manipulating and visualizing data, including CAE and test results, is Altair Compose - an all-in-one environment that enables a wide range of mathematical operations. It also supports process automation and scripting for recurring calculations.

Using multidisciplinary system simulation, Altair Activate enables customers to understand the overall system behavior of their product earlier and evaluate important interactions between components and subsystems. The combination of signal-based and physical modeling forms the basis for end-to-end use throughout the development lifecycle - from early concept through detailed design to hardware-in-the-loop (HIL) testing.

In this workshop, you will learn how Altair Compose and Altair Activate can be used to represent mechatronic systems using holistic functional simulation and will get insights in various case studies.

Our Presenters