Industries are embracing transformative product development through digital twins. When deployed with simulation, HPC, and AI capabilities, digital twins offer unprecedented value by predicting system behavior, leveraging operational data, and informing decision-making at all product lifecycle stages, ensuring a dramatic return on technological investment.

But what is a digital twin?

We define digital twin as a virtual representation of an asset that leverages the convergence of simulation, HPC, and AI to predict and optimize system outcomes.

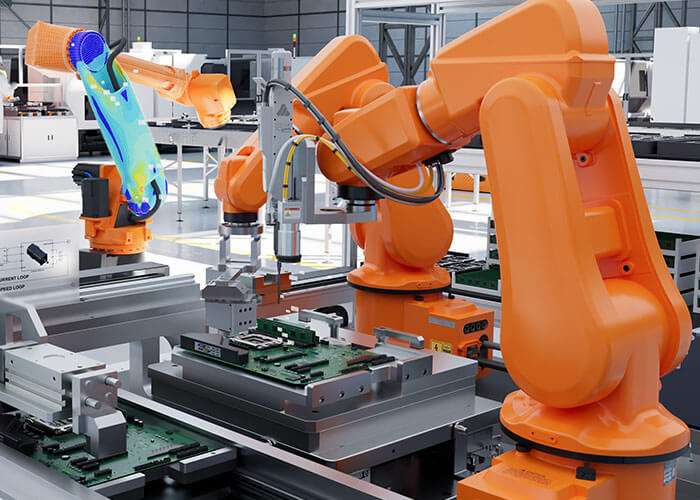

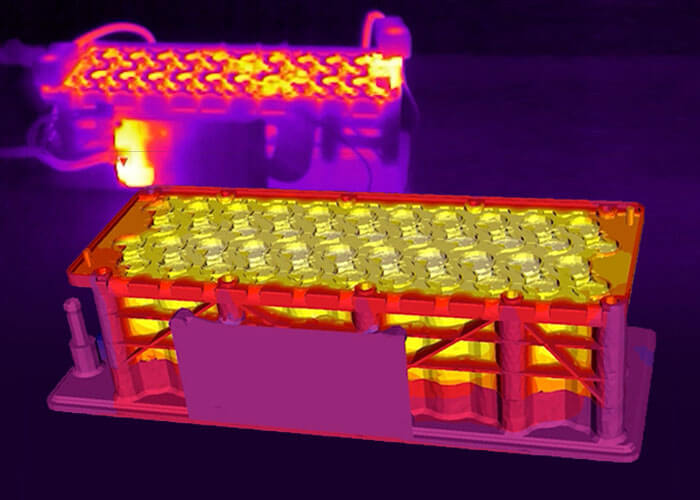

When applied to product development, digital twins enable AI-augmented design exploration that evaluates designs comprehensively, accounting for all system and sub-system interactions. With this approach, designs meet technical requirements faster than with other methods. For systems in operation, physics- and AI-powered digital twins connect and monitor real-world conditions, offering organizations a layer of intelligence to maximize overall equipment effectiveness and minimize maintenance costs.

This webinar series will explore a wide range of digital twins each tailored for a specific application. Based on customer examples you will get to know the core technologies needed to realize valuable digital twins.

Who should attend?

This webinar series addresses the needs and challenges of engineering leaders in product development, manufacturing, and operations. It will provide value to teams focusing on system digitization for durability & structural-health evaluation (OEMs and suppliers), battery design teams (OEMs and suppliers), and operations managers (manufacturing).

We thank our sponsors for webinars 1-4: