Terms of Use | Privacy Notice | Data Privacy Framework | Cookie Notice | DMCA | Whistleblowing |

© Altair Engineering Inc. All Rights Reserved.

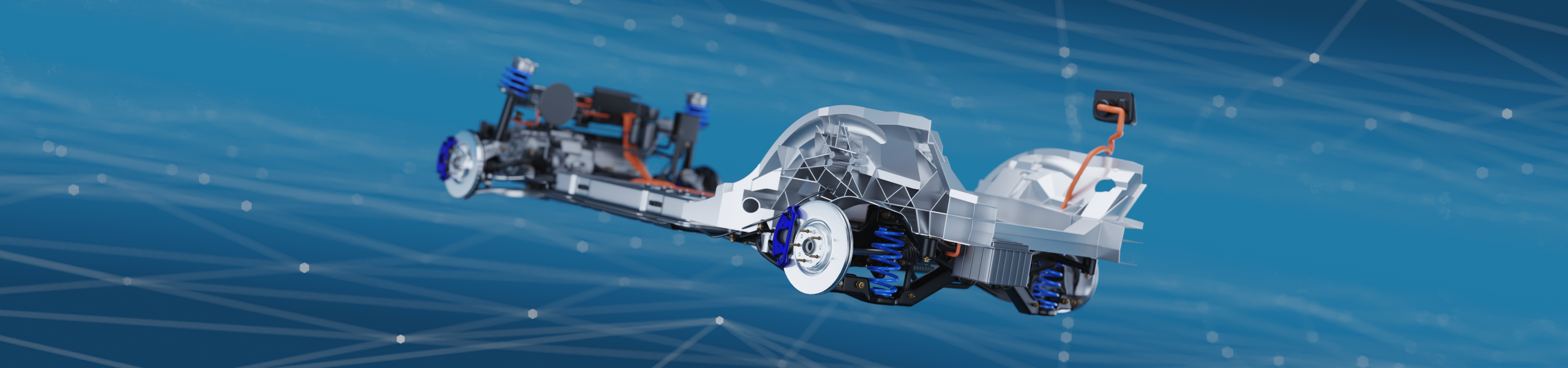

Today’s need for sustainable mobility solutions and the emergence of revolutionary new vehicle concepts has inspired designers to rethink ways of minimizing weight, manufacturing costs, and how to meet the latest performance targets. Reduce the risks involved in moving from the traditional to the new with Altair’s comprehensive solution for developing innovative mega- and gigacasting components. Blending industry knowledge and innovative technologies, explore how a bespoke workflow utilizing Altair's artificial intelligence (AI) and generative design approach, powered by advanced CAE, delivers multidisciplinary automotive design exploration while also allowing teams to leverage thousands of simulations to guide the best way forward.

Get ready to revolutionize your design process with your ultimate guide to AI-powered generative design. Explore cutting-edge insights and expert tips that will redefine the way you approach vehicle design.

Explore Here