Get Sponsorship Licenses for Your Team

Request NowAltair Global Student Team Workshops 2025

Recordings of the Virtual Event (October 7-8, 2025)

Build Better Products Faster. Win More Competitions. Be Real-World-Ready.

See how your team can lightweight components (with topology optimization and composites); analyze aerodynamics to reduce drag; optimize suspension design, steering, and vehicle dynamics & durability; manage electrical power for energy efficiency; and more!

The event features:

-

Student-led sessions from top teams working on vehicles, rovers, satellites, robots, and more -sharing how Altair tools helped them achieve their goals.

-

Altair-led sessions from expert engineers – sharing years of experience with simulation, design optimization, and AI. Including live software demonstrations tailored to competition-related usage scenarios.

Altair Expert

Welcome Day 1 | Altair Software & Support Resources Available to Teams

Team UBC, Canada

Solar Vehicle | Lightweighting (Inspire)

Altair Expert

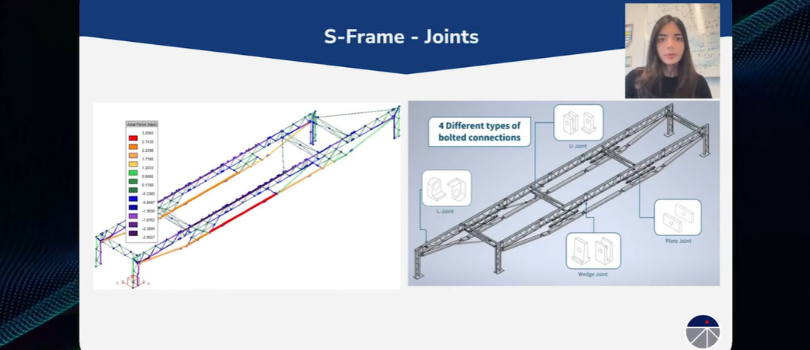

Structural Analysis, Lightweighting & Motion Dynamics (Inspire, SimSolid, OptiStruct & MotionSolve)

Team NSSUR, Korea

Formula Student Vehicle | Structural Analysis, Lightweighting, CFD Flow Analysis (HyperWorks)

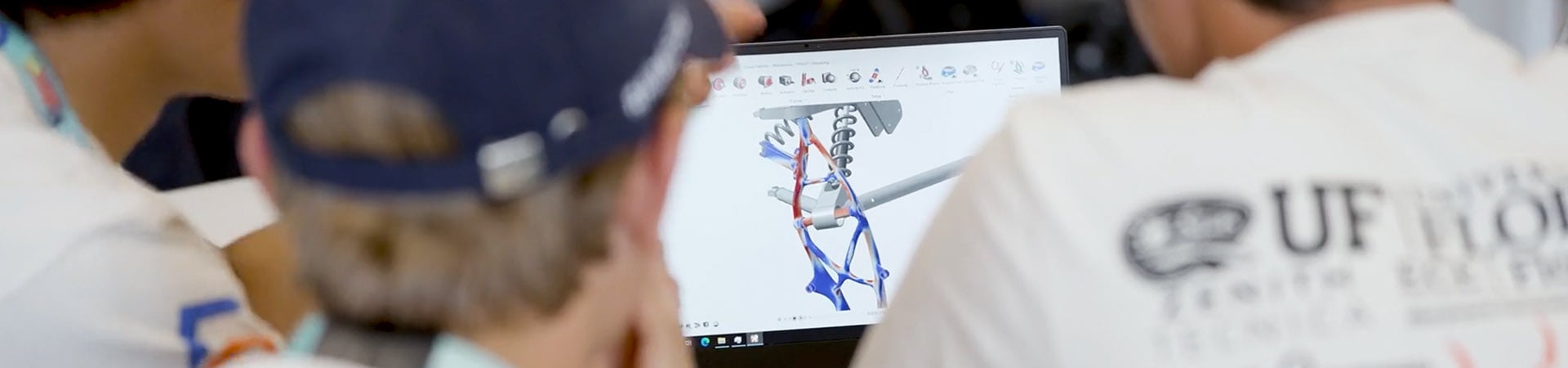

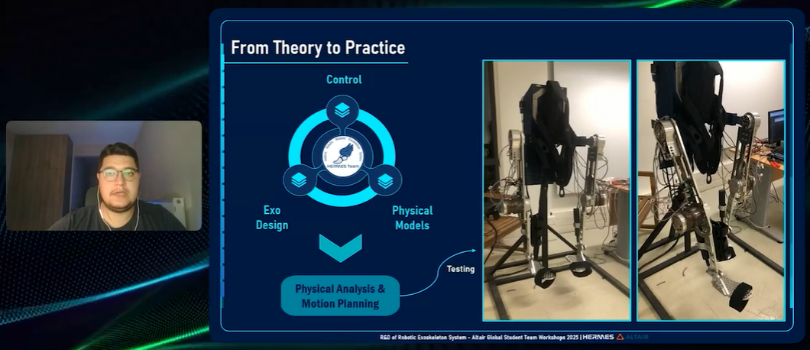

Team HERMES, Greece

Robotic Exoskeletons | Digital Twins, Structural Analysis, Motion Dynamics, Systems Modeling, PCBs, Electronics Cooling (OptiStruct, MotionSolve, Twin Activate, SimLab)

Altair Expert

Aerodynamics (FlightStream)

Team TU Delft Brunel Solar, Netherlands

Solar Vehicle | Reducing Aerodynamic Drag, Rapid Design Iteration (FlightStream)

Altair Expert

Ground Vehicle Dynamics, Suspension Design (MotionSolve, MotionView)

Team NJIT Highlander Racing, USA

Baja SAE | Suspension Design, Kinematics & Compliance, Vehicle Dynamics (MotionSolve, MotionView)

Altair Expert

Welcome Day 2 | Altair Academic Program for Competition Teams

Siemens Expert

Siemens Academic Program for Competition Teams

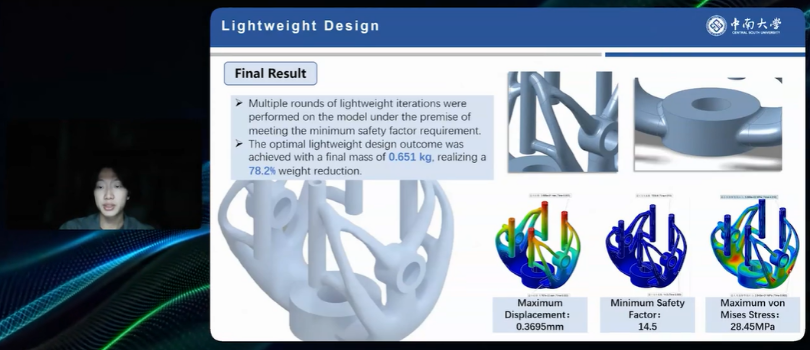

Team CSU, China

Orbital Intelligent Inspection Robots | Structural Safety, Lightweighting, Data Analysis, Machine Learning, AI (Inspire, Monarch, AI Studio)

Team Oxford Brookes Racing, UK + Altair Expert

Formula ICE Vehicle | Composites (HyperMesh, OptiStruct)

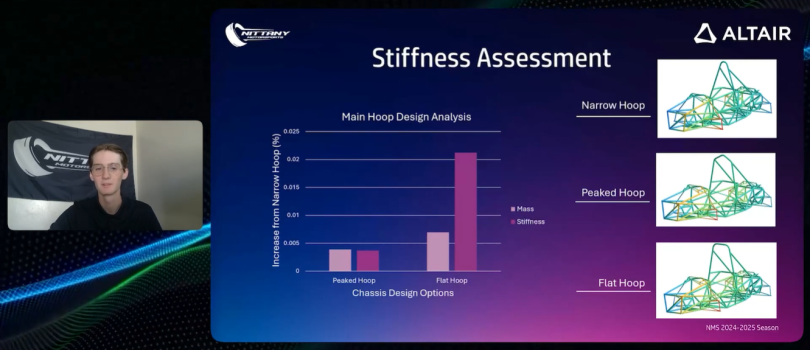

Team PSU Nittany Motorsports, USA

Formula Electric Vehicle | Tubular Chassis Design | Structural Analysis, Rapid Design Iteration with Large Assemblies (SimSolid)

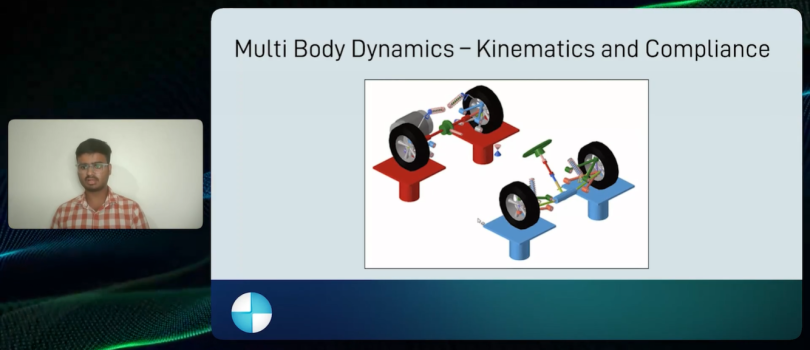

Team Veloce Racing, India

Formula Electric Vehicle | Structural Analysis, Composites, Lightweighting, Kinematics & Compliance, Crash (HyperMesh & OptiStruct, MotionSolve, Radioss)

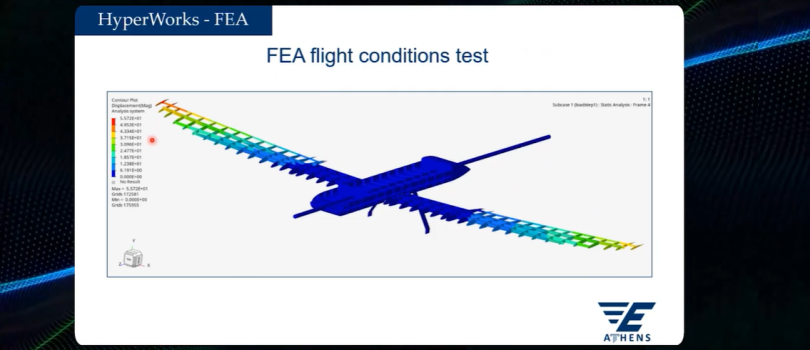

Team EUROAVIA, Greece

UAVs | Structural Analysis, Lightweighting, Composites, Aerodynamics (HyperWorks)

Altair Expert

Electric Vehicles | Faster eDrive Efficiency Mapping (PSIM, HyperStudy)

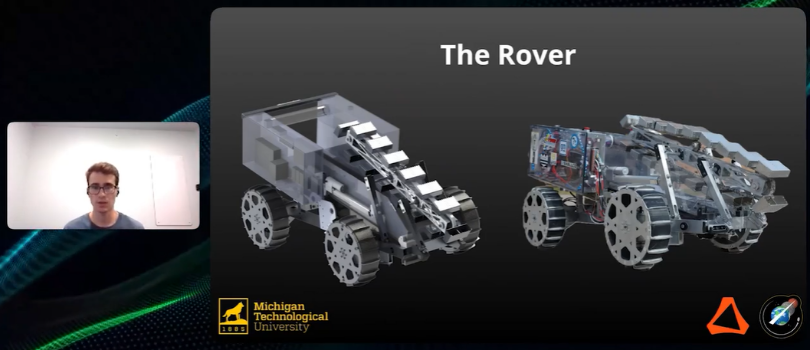

Team MTU Astro-Huskies, USA

NASA Lunabotics Challenge: Off-World Rover | Topology Optimization, Design Exploration (Inspire)

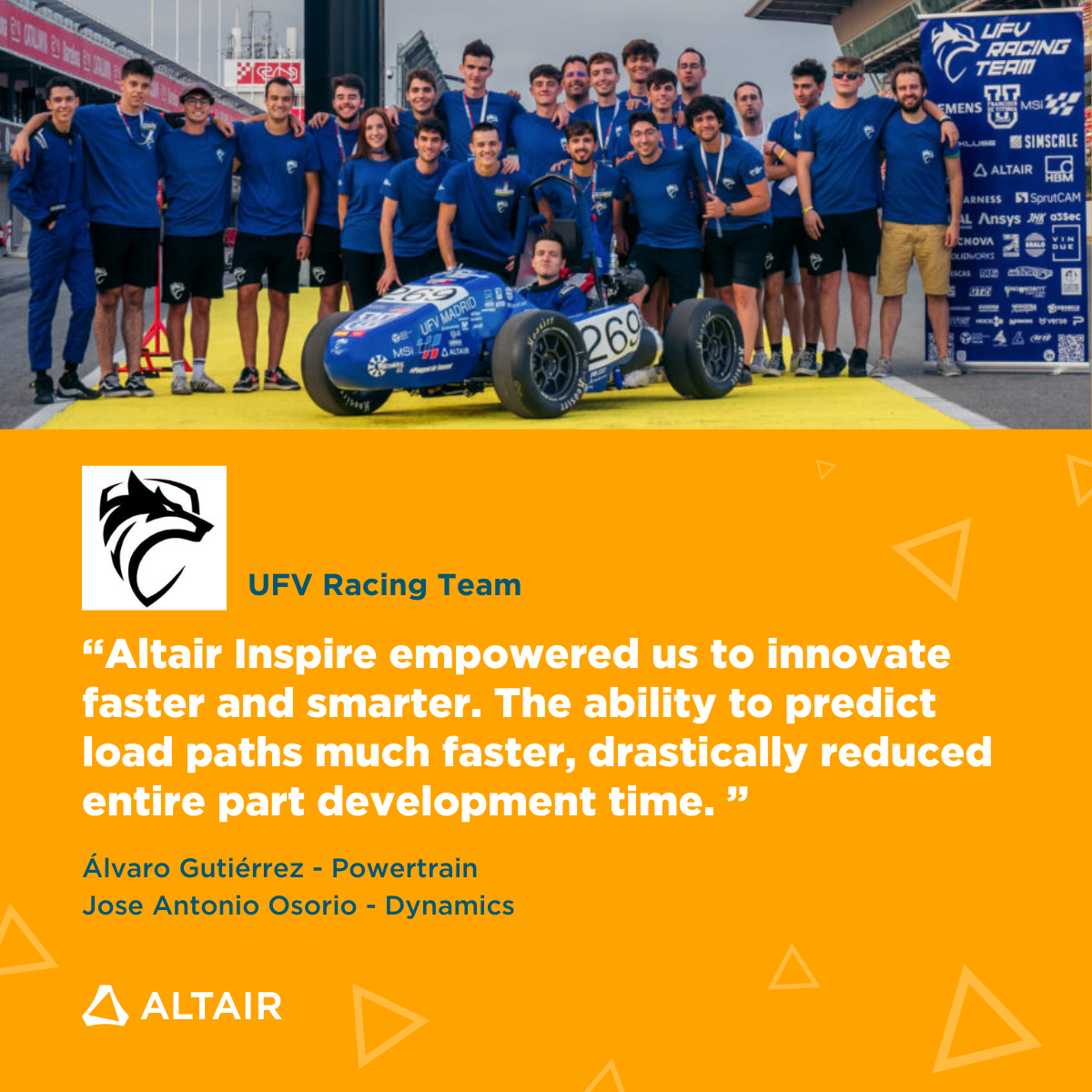

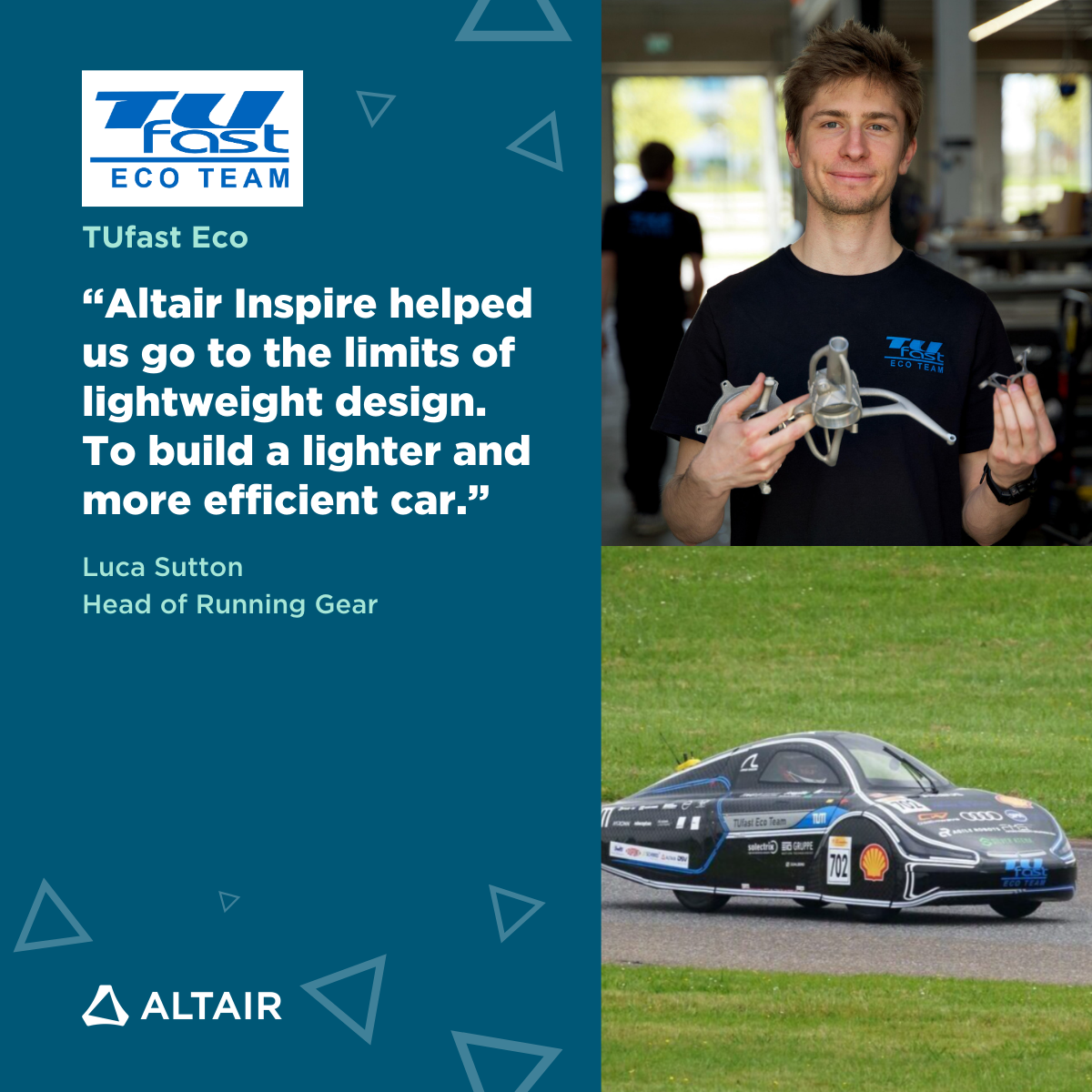

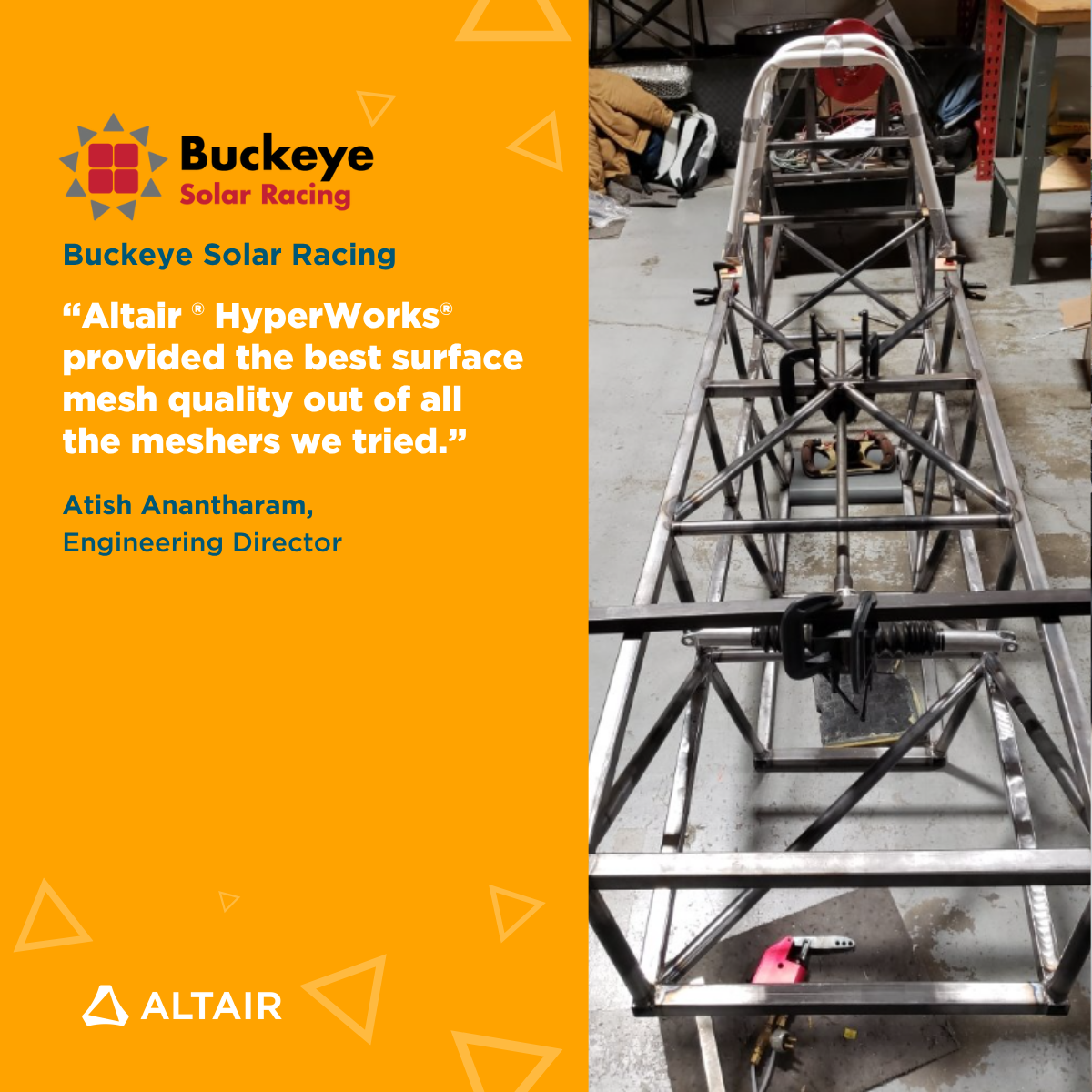

Student Team Testimonials

-Sep-03-2025-09-38-07-7003-PM.png)